Choosing the Right High Bay Light Fixtures for Industrial and Commercial Spaces: Features, Efficiency, and Mounting Options

You have special problems when lighting big spaces with high ceilings like warehouses or factory floors. The right High Bay Light Fixtures can change these places. They help by making it easier to see, lowering eye strain, and cutting down on accidents. Studies show that places with modern Led Light solutions have fewer work accidents. Workers also get more done because they can see better and feel less tired. If you run a Home distribution center, manage Product assembly, or look at About Us pages for new projects, picking the right lights will make things safer, more comfortable, and more efficient.

Key Takeaways

Pick high bay light fixtures that fit your ceiling height. This helps make the light bright and even. It also helps stop shadows from forming. - Pick LED high bay lights to save energy. They last a long time and do not need much fixing. - Use the right way to mount your lights, like hooks or mounts. This keeps the lights safe and easy to take care of. - Plan where to put your lights by looking at your space and work spots. This stops dark areas and helps keep people safe. - Think about all costs, like energy and fixing, to get the best deal. This helps you save money in the long run.

Key Factors for High Bay Light Fixtures

Ceiling Height

Ceiling height is very important when picking High Bay Light Fixtures. Most big work spaces have ceilings from 15 to 40 feet high. The ceiling height tells you how much light will reach the floor. It also helps you know how many fixtures you need. If your ceiling is 15 to 20 feet, put fixtures at 12 to 18 feet. For ceilings between 20 and 30 feet, place fixtures at 18 to 24 feet. If your ceiling is over 30 feet, put fixtures at 24 to 30 feet. Use high lumen output and narrow beam angles for strong lighting on the floor.

Recommended Installation Height (feet) | Additional Notes | |

|---|---|---|

15 - 20 | 12 - 18 | Suitable for many commercial and industrial spaces |

20 - 30 | 18 - 24 | Use broader beam angles and higher lumen output for coverage |

Above 30 | 24 - 30 | Needs high lumen output and narrow beam angles |

Tip: Taller ceilings need stronger fixtures or more lights for good brightness. How high you hang the lights changes how well the light spreads.

Space Layout

The way your space is set up changes your lighting plan. Warehouses are often long with aisles and tall shelves. These spaces do best with a grid pattern for lights. This helps stop shadows and dark spots. Factories may have different work areas, each needing its own amount of light. You should think about the shape of your space, ceiling height, and things like shelves or machines that block light.

Long spaces with aisles need linear fixtures for even light.

Work areas may need extra fixtures for more brightness.

Shiny surfaces let you put fixtures farther apart.

Dark walls or floors mean you need lights closer together.

Where aisles and equipment are placed also matters for fixture choice. Linear LED high bays are good for spaces with aisles. Their shape fits the layout and helps stop shadows. UFO-style fixtures are best for open areas with high ceilings. They focus light where you need it most.

Energy Efficiency

Energy efficiency is very important when picking High Bay Light Fixtures. Changing from old lights to LED high bay fixtures can save 40% to 60% on energy bills. LEDs give 120-150 lumens per watt, which is much better than old lights. This means you get more light but use less power. Your bills go down and you help the environment.

Technology | Lumen Output (Approx.) | Lifespan (Hours) | Lumen Depreciation | Heat Production | Warm-up Time | Maintenance | Additional Notes | |

|---|---|---|---|---|---|---|---|---|

Metal Halide | 400-455 | 25,000-35,000 | < 20,000 | Loses ~50% in 1-2 years | Up to 350°F | Up to 15 min | High | Contains mercury; long restart delay |

Fluorescent (T5) | ~32 per bulb | ~3,000 per bulb | ~35,000 | Slower depreciation | Lower | Instant | Moderate | More energy efficient than metal halide |

LED | < 200 | ~20,000 | Up to 150,000 | Minimal | ~100°F | Instant | Low | Uses about half the energy of metal halide; rebates |

Note: LEDs save energy, last longer, and need less fixing. This means less time and money spent on changing lights.

Mounting Options

You need to pick the right way to mount your lights for your space and ceiling height. The right mounting keeps your fixtures safe and spreads light evenly. Here are some common ways to mount your lights:

Mounting Option | Description | Typical Applications |

|---|---|---|

Yoke Mount Bracket | Lets you put UFO lights on flat surfaces and change the angle. | Good for sloped or low roofs that need angle changes. |

Suspension Hook Mount | Hangs lights from the ceiling with chains or cables; easy to set up. | Most popular; works with many ceiling types. |

V-Hooks | Hooks screw onto the fixture and lock in place. | Used for hanging from ceilings or raised surfaces. |

Surface Mount | Fixed bracket; puts fixture close to ceiling for more space. | Best for places with little vertical space. |

Rod and Plate Mount | Uses rods to connect the fixture to a ceiling plate; looks nice. | Good for stylish hanging in indoor spaces. |

Pro Tip: Suspension hook mounts are flexible for most big spaces. Surface mounts are best when you need to save space above.

Picking the right mounting helps your High Bay Light Fixtures work their best. Always think about ceiling height, space layout, and what kind of work happens there before you choose.

Types of High Bay Light Fixtures

LED High Bay Lights

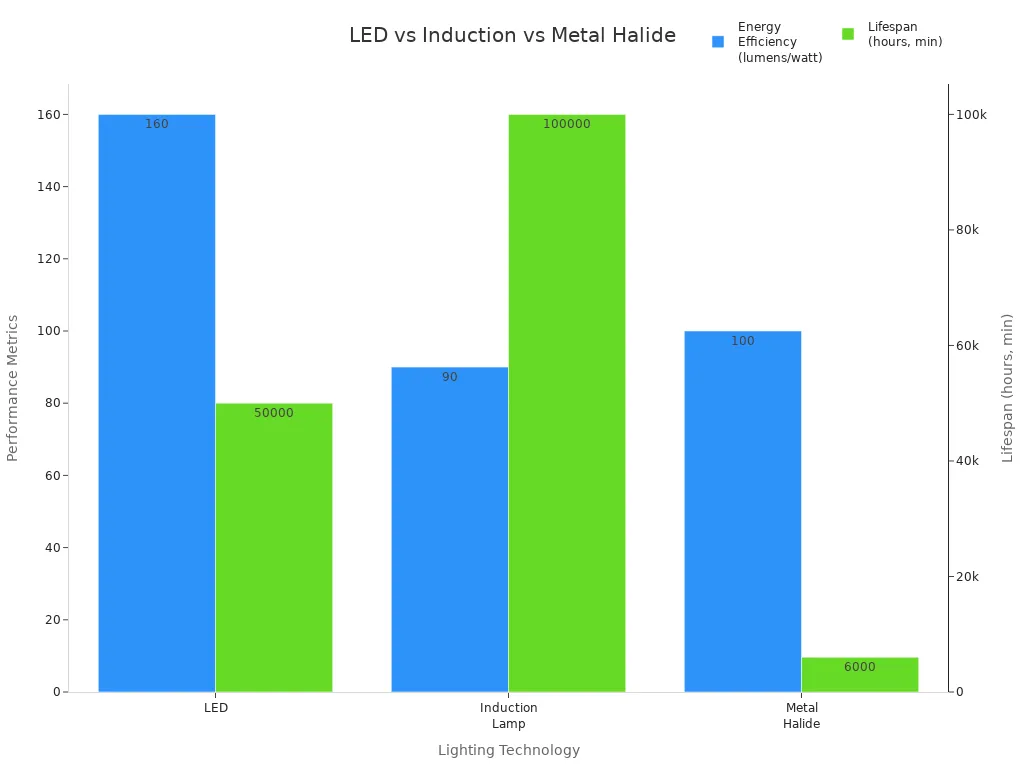

You get the best performance and savings with LED high bay lights. LEDs use up to 160 lumens per watt and last from 50,000 to 100,000 hours. You spend less on energy and maintenance because LEDs keep over 90% of their brightness for years. They turn on instantly and do not waste energy as heat. You can dim them and control them easily. These features make LEDs the top choice for most industrial and commercial spaces.

Feature | LED | Induction Lamp | Metal Halide (Ceramic Metal Halide) |

|---|---|---|---|

Energy Efficiency | Up to 160 lumens per watt | ~90 lumens per watt | 80-100 lumens per watt |

Lifespan | 50,000 to 100,000+ hrs | Hundreds of thousands hrs | 6,000 to 15,000 hrs |

Maintenance Costs | Low | Very low | Moderate |

Light Control | Superior (dimmable, focused) | Poor (360° unfocused) | Moderate |

Heat Generation | Low | Low | High |

LED high bay lights give you the best mix of energy savings, long life, and easy control.

UFO and Round Fixtures

UFO and round high bay lights work well in open areas with high ceilings. You find them in warehouses, factories, and sports arenas. These fixtures give you bright, even light and fit many mounting styles. They last up to 50,000 hours and use less power than older lights. Their compact shape makes them easy to install and maintain. You can use them in tough environments because they resist dust, moisture, and impact.

High energy efficiency and long lifespan

Uniform, wide light coverage

Instant on/off with no warm-up time

Durable and safe for industrial use

UFO fixtures help you save on electricity and reduce maintenance in busy, open spaces.

Linear and Strip Fixtures

Linear and strip high bay lights work best in spaces with aisles or long rows, such as warehouses, retail stores, and gyms. These fixtures give you a wide, rectangular beam that covers shelves and aisles evenly. You avoid dark spots and glare, making your space safer and easier to work in.

Use linear fixtures in warehouses with tall shelves to get even light in every aisle.

Choose them for retail stores to create a bright, inviting space.

Install them in gyms or sports halls for safe, clear lighting.

Linear fixtures reduce wasted light and energy in long, narrow spaces.

Linear high bays give you the best results in spaces where you need light to reach every corner.

Other Technologies

You may still see induction or metal halide high bay lights in older buildings. Metal halide lamps give good color but use more energy and need frequent replacement. Induction lights last longer than metal halide but do not match the energy savings of LEDs. Both types cost more to run and maintain over time.

Lighting Type | Daily Cost | Monthly Cost | Annual Cost | Savings over 5 Years (vs Metal Halide) | |

|---|---|---|---|---|---|

Metal Halide | $300 | $9,000 | $108,000 | $540,000 | N/A |

Induction Lighting | $180 | $5,400 | $64,800 | $324,000 | $216,000 |

LED High Bay Lights | $100 | $3,000 | $36,000 | $180,000 | $360,000 |

Over five years, LED High Bay Light Fixtures can save you hundreds of thousands of dollars compared to older technologies.

Essential Features to Compare

Lumen Output

You need to pick the right lumen output for your space. Medium lumen output, from 21,000 to 35,000 lumens, is good for most big warehouses and stores. Smaller rooms or less important areas can use lights with 4,000 to 20,000 lumens. If you work in a factory and need to see details, you may need 20,000 to 40,000 lumens for each fixture. Always think about how high your ceiling is. For example, a warehouse with a 30-foot ceiling needs about 30,000 lumens per fixture for bright, even light.

Warehouses (20-30 ft ceilings): 20,000-30,000 lumens per fixture

Manufacturing (15-25 ft ceilings): 20,000-40,000 lumens per fixture

Higher ceilings (25-40 ft): 25,000-60,000 lumens per fixture

Tip: The right lumen output helps stop dark spots and keeps people safe and working well.

Beam Angle

Beam angle tells you how the light spreads in your building. If your ceiling is high, use a narrow beam angle. This points the light down and keeps it strong. For lower ceilings, a wide beam angle spreads the light out more.

Ceiling Height | |

|---|---|

High ceilings | Narrow beam angles |

Low ceilings | Wide beam angles |

A narrow beam angle keeps work areas bright, even if the lights are far from the floor.

Color Temperature & CRI

Color temperature and CRI help you see better and work safely. A color temperature of 5000K is like daylight and is best for most big work spaces. Some places may want 4000K for a softer look. You should pick a CRI between 80 and 95. High CRI makes colors look real, helps your eyes, and keeps you safe.

5000K: Bright, like daylight, great for warehouses and factories

4000K: Neutral white, good for comfort and clear sight

CRI 80-95: Makes colors look right and helps stop tired eyes

Dimming & Controls

Many High Bay Light Fixtures have smart controls and dimming. You can use wireless sensors to see when people are there and change the brightness. Smart dimming, like 0-10V, lets you set the light for different jobs. Daylight sensors change the lights when the sun is out, so you save energy. Cloud controls let you check and change your lights from far away.

Dimming helps save energy and makes lights last longer

Sensors stop you from wasting power

Remote controls make fixing lights easier

Lifespan & Maintenance

You want lights that last a long time and do not need much fixing. LED High Bay Light Fixtures last 50,000 to 100,000 hours. This is much longer than metal halide or fluorescent bulbs, which last only 7,000 to 20,000 hours. Longer life means you change lights less and spend less money on repairs.

Lighting Technology | Average Lifespan (hours) |

|---|---|

LED High Bay Fixtures | 50,000 - 100,000 |

Metal Halide / HPS | 10,000 - 20,000 |

Fluorescent Bulbs | 7,000 - 15,000 |

Incandescent Bulbs | 750 - 2,000 |

Picking lights that last longer means less downtime and your building keeps running well.

Mounting and Installation

Suspension Mount

Suspension mounts let you hang lights from the ceiling. You use cables, rods, or chains to do this. You can change the height to fit your space. This is good for ceilings that are not flat. It also helps when you want to lower the lights for better lighting. Warehouses and factories with high ceilings often use suspension mounts. These mounts help you point light where you need it. They also make it easier to fix the lights because you can reach them without special lifts.

Tip: Use cables you can adjust for quick height or angle changes. This helps if you move things around in your space.

Surface Mount

Surface mounting puts the light right on the ceiling or a beam. This saves space because the light is close to the ceiling. Use surface mounts in rooms with low ceilings. They also look neat and simple. Surface mounts work well in places with lots of shaking, like factories. The light stays steady and does not move much.

Good for rooms with low ceilings

Stops lights from moving in busy places

Makes the room look tidy

Hook & Chain Mount

Hook and chain mounts are strong and flexible. You can pick from different hooks, like clevis grab hooks, slip hooks, S-hooks, and self-closing hooks. Each hook type has its own good points:

Clevis grab and slip hooks hold the light tightly. The size of the hook opening changes how you set things up.

Chains are strong but do not let you change the length easily.

S-hooks are cheap and can be used in many ways. But they might not stay tight if the light is heavy or shakes a lot.

Flat hooks have a wide area that helps stop slipping.

Self-closing hooks have a spring latch for extra safety. This is good if the chain gets loose.

Always follow OSHA and ASME rules for safety. Safety latches stop the light from falling by accident. Pick the right hook and check them often to keep your lights safe.

Installation Height Considerations

You need to think about a few things when picking how high to put your High Bay Light Fixtures. Ceiling height, beam angle, lumen output, and what work you do all matter. High ceilings need lights with more lumens and a narrow beam angle. This helps the light reach the floor. Low ceilings work better with wide beam angles for even light. If people do detailed work, put the lights lower for more brightness.

Power Range (W) | Recommended Installation Height (meters) | Typical Applications |

|---|---|---|

4 - 6 | Warehouses, garages, low-rise factories | |

200 - 250 | 6 - 8 | Medium warehouses, manufacturing workshops |

300 - 400 | 8 - 12 | Large warehouses, logistics centers |

500 and above | Over 12 | High-ceiling environments like stadiums |

You get the best lighting when you match fixture power and beam angle to your ceiling height and needs.

Selection Checklist

Assess Space & Height

First, measure your building. Write down the length, width, and ceiling height. These numbers help you know how many fixtures you need. They also show where to put each fixture. If your ceiling is 20 feet high, space the fixtures about 20 feet apart. Use a spacing-to-height ratio from 0.5 to 1.5 for even light. Look at the ceiling type and find any beams or ducts in the way. Check your lights every year to keep them safe and working well.

Tip: Try a lighting calculator or ask an expert for the best fixture spots.

Determine Light Levels

Think about what jobs happen in each area. Set your lighting goals to match the work. Follow the rules for how bright it should be. For most work, use 300-750 lux. For careful jobs, use 1000-2000 lux. Use the formula E = Φl × Cu × LLF / Al to guess how much light you get. Φl is lamp output, Cu is utilization, LLF is light loss, and Al is area per lamp. Watch out for glare, shadows, and dark spots. Good lighting keeps people safe and helps them work better.

Task Type | Recommended Illuminance (lux) |

|---|---|

General Assembly | 300-750 |

Precision Manufacturing | 1000-2000 |

Workshops | 600-700 |

Evaluate Environment

Look around your building for heat, cold, water, dust, and shaking. Hot places can make lights dim or break faster. Cold rooms may make lights start slow or get wet inside. Water and dust can cause rust or power problems. Pick fixtures with strong heat sinks and vapor-tight covers. Choose tough materials that last. Find models that work from -30°C to 50°C or more. Tempered glass and sealed cases help lights last longer in hard places.

Fast temperature changes can crack or break lights.

Water and dust can cause power shorts.

Strong, sealed fixtures protect your money.

Budget & Cost Savings

Look at the total cost, not just the price tag. LED fixtures use up to 75% less energy than old lights. Most places get their money back in 2-3 years. LEDs last 5 to 10 times longer, so you fix them less. You might save $300 per fixture each year on power. Rebates and deals can make new lights cheaper. Fewer changes mean less work and less time wasted.

Note: Better lighting also makes people safer and helps them do more, so you get extra value.

You now have the tools to choose the best lighting for your space. Match fixture type to ceiling height for the best results. Focus on energy efficiency to lower costs and improve performance. Select the right mounting method for safety and easy maintenance. Use the checklist to guide your decisions. If you feel unsure, talk to a lighting expert. Start by reviewing your current setup and plan your next steps for better lighting.

FAQ

What is the best high bay light fixture for energy savings?

LED high bay fixtures give you the best energy savings. You use less power and get more light. LEDs also last longer than other types. You save money on both energy and maintenance.

How do I know how many high bay lights I need?

Measure your space. Check the ceiling height and area size. Use a lighting calculator or ask an expert. You want even light with no dark spots. Most spaces need one fixture every 15 to 20 feet.

Can I install high bay lights myself?

You can install some high bay lights if you have basic electrical skills. Always follow safety rules. For large projects or high ceilings, hire a licensed electrician. This keeps your building safe and up to code.

Do high bay lights work in cold or wet areas?

Yes, many high bay lights work in cold or wet places. Look for fixtures with IP65 or higher ratings. These lights resist water and dust. They also start well in low temperatures.

See Also

Industrial LED High Bay Lighting Uses And Installation Tips

Comprehensive Overview Of High Bay Light Types And Uses

Choosing LED High Bay Lights Based On Benefits And Uses