How Industrial LED Lamps Stack Up Against Traditional Lighting

Industrial LED lamps save more energy and last much longer than old lights. They also help companies save a lot of money. LED lamps can use up to 90% less energy. They can last over 50,000 hours. Maintenance costs can drop by as much as 80%. The table below shows how industrial LED lamps are better in every important way. This includes being stronger, safer, and better for the environment.

Metric | LED Lighting Advantage | Traditional Lighting Comparison |

|---|---|---|

Energy Consumption | Up to 75% reduction | Higher energy use |

Lifespan | Exceeds 50,000 hours | 1,000-2,000 hours |

Maintenance Costs | Significantly reduced | Frequent replacements |

Environmental Impact | No hazardous materials | Contains mercury, higher emissions |

Industrial LED lamps are the best choice for factories and big buildings. You can use them for new products or to upgrade old lights. Companies that want to save energy and help the planet can learn more on the Home or About Us pages.

Key Takeaways

Industrial LED lamps use up to 75% less energy. They last much longer than old lights. This helps save money and lowers the need for repairs.

LED lights make places safer. They turn on right away. The light spreads out evenly. They do not have dangerous stuff like mercury.

Changing to LED lighting can lower energy bills by up to 60%. The money spent on LEDs is often paid back in two to four years.

LED lamps give better light. Colors look clearer. There is less flicker. This helps workers see better and do their jobs well.

Picking LED lighting helps the environment. It makes less pollution. It cuts down on waste. The materials can be recycled.

Overview

Industrial LED Lamps

Industrial LED lamps have changed how factories use lights. These lamps use new technology to save energy and last longer. Most factories now pick LED high bay lighting for big rooms with tall ceilings. This lighting uses less power and makes less heat than old lights.

Many companies like LED lights because they have smart features. Over 60% of new lights have IoT controls. These let workers change brightness and set schedules by themselves. LED lights also help people feel better at work. They can change color to make workers more comfortable and help them work better. New materials, like GaN-on-Silicon, help control heat and lower costs.

Industrial LED lamps can work with solar and wind power. This means they do not need the main power grid as much. AI can help fix problems before they get worse. This can cut downtime by up to 40%. All these things make LED lighting the best choice for today’s factories.

Note: In developed places, more than 75% use LED lighting. This is because of strict energy rules and goals to protect the planet.

Key Performance Indicator | Industrial LED Lamps (Recent Benchmarks) |

|---|---|

Energy Efficiency | 30-70% energy savings |

Market Adoption | Over 75% in developed regions |

Smart/IoT Integration | Over 60% with smart controls |

Sustainability | Recyclable materials, carbon neutrality initiatives |

Operational Cost Savings | Adaptive lighting reduces costs |

AI-Driven Predictive Maintenance | Up to 40% downtime reduction |

Human-Centric Lighting | Dynamic color temperatures |

Advanced Materials | GaN-on-Silicon substrates |

Energy Autonomy | Hybrid power integration |

Traditional Lighting

Traditional lighting means using fluorescent, metal halide, or incandescent lamps. These old lights use more energy and need to be replaced often. Most do not have smart features or connect to new control systems.

Traditional lights can have dangerous stuff inside, like mercury. This can hurt the environment. They only use regular power and cannot use solar or wind. Old lights break more, so fixing them costs more money.

In many places, people use traditional lights less now. New rules and rewards make LED lighting a better choice. Old lights do not have human-friendly features or new materials. They also cannot save as much money as LED high bay lighting.

Fewer people are using traditional lighting around the world.

Most old lights cannot use smart controls or automation.

Fixing and powering old lights costs more than LED lights.

Traditional lighting does not help with saving the planet.

Direct Comparison

Energy Efficiency

Industrial LED lamps use much less energy than old lights. LED lighting can use up to 44% less energy than fluorescent lights. They save between 31% and 84% more energy than other old lights. Most old lights, like metal halide or high-pressure sodium lamps, use more electricity. These old lights waste a lot of energy as heat. LED lights turn more power into light you can see. This means less energy is wasted. Using LED lighting helps lower electric bills. It also helps the planet by making less pollution.

Feature | LED Lighting | Traditional Lighting |

|---|---|---|

Energy Efficiency | Up to 44% less energy | Less efficient |

Energy Savings | 31%–84% | Baseline (100% usage) |

Tip: When places switch to LED lights, they often get their money back in two to four years because they save so much energy.

Lifespan

LED lights last much longer than old lights. Industrial LED lamps can work for 25,000 to 50,000 hours. Fluorescent lights only last 7,000 to 15,000 hours. Incandescent bulbs last about 1,000 hours. Because LED lights last longer, you do not have to replace them as often. This means less time fixing lights and fewer breaks in work. LED lights stay bright for many years. They are a good choice for places that need lights on all the time.

Lighting Type | Average Lifespan (hours) |

|---|---|

Industrial LED Lamps | 25,000 – 50,000+ |

Fluorescent Lighting | 7,000 – 15,000 |

Incandescent Bulbs | ~1,000 |

A long-lasting light means you spend less money fixing or throwing away lights. This helps save money and is better for the environment.

Cost

Cost is important when picking lights. LED lights cost more at first than old lights. But over time, LED lights save more money. They use less energy and do not need to be replaced as much. This makes the total cost lower in the end. Old lights may be cheaper to buy, but you pay more later. You have to fix them more and pay bigger electric bills.

Factor | Industrial LED Lamps | Traditional Lighting (HPS, MH, Fluorescent) |

|---|---|---|

Initial Cost | Higher initial investment | Lower upfront cost |

Lifetime Cost | Lower due to energy and maintenance savings | Higher due to frequent replacements and energy use |

Cost Savings | Up to 60% annual reduction | Higher ongoing costs |

Note: Many companies save money for years and get their money back fast when they switch to LED lighting.

Light Quality

LED lights give better light than old lights. Industrial LED lamps have a Color Rendering Index (CRI) of 80 to 90 or more. This means colors look more real and clear. Old lights almost never have a CRI above 80. LED lights turn on right away and shine evenly. They do not flicker much. The light goes where you need it, so you see better and there are fewer shadows.

Light Quality Metric | Industrial LED Lamps | Traditional Lighting |

|---|---|---|

Color Rendering Index (CRI) | 90 or higher | Rarely beyond 80 |

Usable Light Efficiency | 40% more usable light | Efficiency loss due to reflectors |

Light Directionality | 180°, no reflector needed | 360°, reflector required |

A higher CRI helps people see better and keeps their eyes from getting tired.

LED lights shine evenly, so work areas are brighter and mistakes happen less.

Maintenance

LED lights are easier to take care of. Industrial LED lamps keep up to 70% of their brightness after 50,000 hours. Old lights get dim faster and need to be changed more. If you use an LED light for 10 hours each day, it can last over 13 years. This means you do not have to fix lights as often. Work is not stopped as much for repairs.

Time of Use (Hours) | Lumen Maintenance Coefficient |

|---|---|

0 | 1.00 (100% initial output) |

50,000 | 0.70 – 0.75 (70-75% output) |

Places that use LED lights spend up to 80% less on fixing lights than places with old lights.

Durability

LED lights are tough and work well in hard places. They can handle shaking, bumps, and big changes in temperature. LED lights do not get hot like old lights. They do not burn out all at once. Instead, they slowly get dimmer. Even if some parts stop working, the light still works. This makes them very reliable and stops surprise blackouts.

LED lights work well in cold places and do not break easily.

Old lights can stop working suddenly and need to be replaced more often.

Safety

LED lights make work safer in many ways. They turn on right away, so there are no dark times when you flip the switch. High CRI helps workers see colors right, which means fewer mistakes and accidents. LED lights shine evenly and make fewer shadows, so it is easier to see. LEDs do not have mercury or other dangerous stuff inside. You do not have to fix them as much, so workers are safer and do not have to climb as often.

LED lights help stop accidents by making it easier to see.

LEDs help workers stay alert and do better work, up to 25% more.

No dangerous materials in LEDs means everyone is safer.

Callout: Using LED lights saves money and makes the workplace safer and better for everyone.

LED High Bay Lighting

Industrial Applications

Factories, warehouses, and sports arenas use led high bay lighting. These places have very tall ceilings, from 20 to 45 feet high. Led lights shine bright and light up every part of the room. Workers can see well, so accidents happen less. This helps meet OSHA rules. Led high bay lighting works in tough places with heat, dust, and shaking. Many buildings pick led lights because they last up to 100,000 hours. They also need less fixing.

Led high bay lighting can help stop fires and explosions. This makes it good for hard industrial jobs.

Industrial plants have a lot of shaking, power jumps, and hot or cold air. Led high bay lighting is made strong to handle these problems. Over 60% of factories and warehouses use led high bay lighting now. They like it because it saves energy and works well. Smart controls let managers change the brightness and save even more power.

Benefits

Led high bay lighting does more than just save energy. Led lights turn on right away and can dim smoothly. This helps stop glare and dark spots. Wide beams up to 160° cover the whole area. Led high bay lighting meets strict safety rules and helps people work better by giving clear, even light.

Aspect | Data / Example | Benefit / Impact |

|---|---|---|

Energy Savings | Lower electricity costs | |

Lifespan | 50,000 to 100,000 hours | Fewer replacements, less maintenance |

Luminous Efficacy | 100-150 lumens per watt | More light per watt, less waste |

Payback Period | Often under 2 years | Fast return on investment |

Led high bay lighting makes less carbon and less heat. This means cooling costs go down. Led lights do not have dangerous stuff inside, so they are safer for people and nature. Many companies save 30% to 70% on lighting bills after switching to led high bay lighting. Led lights can use smart features like motion sensors and daylight harvesting. These help save even more energy. The benefits make led high bay lighting the best pick for new industrial buildings.

Environmental Impact

LED Lighting

LED lights are much better for the environment than old lights. They use up to 80% less energy. This helps factories and warehouses save money on power bills. It also means they make less pollution. LED lights last a long time, often more than 50,000 hours. Companies do not have to throw away as many bulbs. This makes less trash. LED lights do not have mercury or other dangerous stuff inside. This makes them safer for people and nature.

Many LED lights have special labels like Energy Star and EPEAT. These show the lights are good for the environment. LED lights are lighter and use fewer parts. This helps lower their impact on the planet. Studies show eco-friendly LED lamps can have up to 60% less impact than old lights. Most of the good comes from using less electricity while the lights are on.

LEDs use up to 80% less energy than old lights.

LED lights last longer, so there is less trash.

There is no mercury or other dangerous stuff in LEDs.

Using less energy means less pollution and fewer greenhouse gases.

LED lighting often meets the best green standards.

Aspect | Details |

|---|---|

Environmental Impact Scores | Up to 60% lower than traditional lighting products |

Product Weight | Lighter, uses fewer materials |

Use Stage Impact Contribution | Over 90% of total impact comes from electricity use |

Key Environmental Benefits | Lower emissions, less waste, safer materials |

LED lighting helps companies reach their green goals. These lights help businesses make less pollution and be better for the earth.

Traditional Lighting

Traditional lighting, like metal halide, high-pressure sodium, and fluorescent lamps, is not as good for the environment. These lights use more power and need nonrenewable energy. This makes more carbon dioxide and raises the carbon footprint of factories. Old lights also make more heat. This can make cooling cost more and use more energy.

Many old lights have dangerous stuff like mercury inside. When these bulbs break or get thrown away, they can let out toxins. Old lights do not last as long. Companies have to change them more often. This makes more trash and costs more to fix.

Old lighting does not meet the same green rules as LED lights. They do not have labels for being good for the earth. They do not help companies be more eco-friendly. Old lights waste more energy and make more greenhouse gases. These problems make old lights a bad choice for companies that care about the environment.

Companies that switch from old lights to LED lights can use up to 80% less energy and make less pollution. This helps make the future cleaner, safer, and better for everyone.

Pros and Cons

Industrial LED Lamps

Industrial LED lamps give many strong benefits to modern buildings. These lamps last a long time and use less energy. They also show colors very well. When places use LED lighting, they can save 60% to 75% on energy. Some LED systems can work for up to 100,000 hours. This means you do not have to change them often. There is less time when lights are off for repairs. LED lights shine in one direction, so more light goes where it is needed. This helps people see better and wastes less light. LED lamps turn on right away. They work well in both hot and cold places. They do not have mercury or other dangerous stuff inside. This makes it safer for workers and the earth when you throw them away.

LED lights can help workers do their jobs better. In factories, they can make people work up to 25% better because the light is brighter and colors look right.

The table below shows the main good and bad things about industrial LED lamps compared to old lights:

Feature/Aspect | Industrial LED Lamps (Pros) | Industrial LED Lamps (Cons) |

|---|---|---|

Lifespan | Higher initial cost | |

Energy Efficiency | 60-75% energy savings; up to 90% in some cases | Requires specific dimming hardware |

Color Rendering Index (CRI) | High CRI (65-95), excellent color accuracy | |

Light Emission Directionality | 180°, reduces losses and need for reflectors | |

Design Flexibility | Small size, versatile applications | |

Dimming Capability | Can dim from 0-100% | |

Turn-On Time | Instantaneous | |

Environmental Safety | No mercury or hazardous materials | |

Heat Emission | Minimal heat generated | |

UV Emissions | Virtually zero | |

Operating Voltage | Often low voltage, suitable for sensitive environments | |

Temperature Range | Performs well in cold and hot environments |

Traditional Lighting

Some places still use traditional lighting, but these lights have many problems. Old lights like fluorescent, metal halide, and incandescent bulbs do not last long. You have to change them a lot, which means more work and more times when lights are off. These lights use more energy, sometimes up to 85% more than LED lights. Using more energy costs more money and is worse for the planet.

Traditional lights shine in all directions. You need reflectors to point the light where you want it. This wastes some of the light. Many old lights cannot dim or take a long time to get bright. Some, like fluorescent and mercury vapor lamps, have dangerous stuff inside. You must be careful when throwing them away. Old lights also make more heat, so cooling big rooms costs more.

Places that use old lights pay more for power. They also have to fix lights more often and face more safety problems.

The table below shows the good and bad things about traditional lights:

Feature/Aspect | Pros of Traditional Lights | Cons of Traditional Lighting |

|---|---|---|

Initial Cost | Lower upfront cost | Higher long-term cost due to replacements and energy use |

Familiar Technology | Well-known, easy to source | Short lifespan, frequent failures |

Availability | Widely available | Poor energy efficiency, high heat emission |

Dimming Capability | Some types can dim | Often inefficient or not possible |

Environmental Impact | None | Contains mercury, hazardous disposal required |

Light Quality | Acceptable for basic needs | Poor color rendering, flicker, and slow warm-up |

Durability | N/A | Fragile, sensitive to vibration and temperature changes |

Safety | N/A | UV emissions, higher risk of accidents during maintenance |

Some places keep using old lights because they cost less at first or people know how to use them. But over time, the problems are bigger than the small savings. Newer LED lights are better for work, safety, and saving money.

Decision Guide

Key Factors

Picking the right lights for a factory is important. You need to look at how well the lights work. Facility managers should check both led and traditional lighting. Here are the main things to think about:

Luminous flux (lumens): This tells you how much light comes from the fixture. More lumens mean the room is brighter. Bright rooms help keep people safe and help them work better.

Efficacy (lumens per watt): This shows how well the fixture uses energy to make light. Led fixtures usually give more light with less power. This helps save money on electricity.

Illumination intensity (lux) and zonal lumen distribution: These show how evenly the light spreads in the room. Even lighting means there are fewer shadows and less glare.

Correlated color temperature (CCT) and color rendering index (CRI): These affect how colors look under the lights. Led fixtures can have a CRI up to 100. This makes colors look real and easy to see.

Rated lifetime and maintenance costs: Led fixtures last much longer than old lights. This means you do not have to change them as often. You also spend less money fixing them.

Environmental protection, heat emission, and fixture design: Led fixtures make less heat and often use parts that can be recycled. This helps protect the planet.

Smart technology integration: Many led systems let you dim the lights or set timers. Old lights usually cannot do this.

Key Factor | Benchmark / Range | Importance |

|---|---|---|

Lumen Output | Measured in lumens | Brighter, safer workspaces |

Power Consumption | 30-90 Watts (led high bay) | Lower energy use |

Energy Efficiency | High lumens per watt | Cost and energy savings |

Color Temperature | 3000K–6000K | Visual comfort, task suitability |

CRI | Up to 100 | Accurate color rendering |

Lighting Quality Metrics | Uniformity, glare, illuminance | Worker comfort and safety |

Economic Factors | Payback period, IRR | Financial decision-making |

Checklist

Facility teams can use this checklist to help pick the best lights:

Look at the size and shape of the room. This helps you know how much light you need.

Check if the area has special needs, like high ceilings or lots of dust.

Compare how much light and power led and old lights use.

Make sure the color temperature and CRI are good for the work.

Think about how long the lights last and how often you need to fix them.

Remember that led fixtures can use 40-50% less energy than old lights.

Check power quality, like power factor, to make sure the lights work well.

See if led systems have smart features, like dimming or timers.

Make sure the lights are safe and meet environmental rules.

Figure out how long it will take to save money with the new lights.

Tip: Picking lights that fit your building’s needs helps everyone work better. It also saves money and keeps the place safe.

Industrial LED lamps work better than old lights in every way. When places use LED lighting, they can cut power use by half. This saves about $0.32 for each square foot every year. The table below shows these good points:

Metric / Finding | Value / Description |

|---|---|

Power use from lighting | 55% in warehouses |

Power reduction after LED retrofit | Up to 50% |

Annual savings for 100,000 sq ft unit | $32,000 |

LED fixture lifespan | Up to 5x longer |

Carbon emissions reduction | 43,453 metric tons |

Most managers say LED lighting is very important for their work. The LED lamp market will keep getting bigger. New smart features and better energy savings will come soon. Facility teams should use the checklist above to pick the best lights for their needs.

FAQ

What is the main reason factories switch to industrial LED lamps?

Factories pick industrial LED lamps because they save energy. These lamps last much longer than old lights. They help lower electric bills and need less fixing. LED lamps also help companies follow safety and green rules.

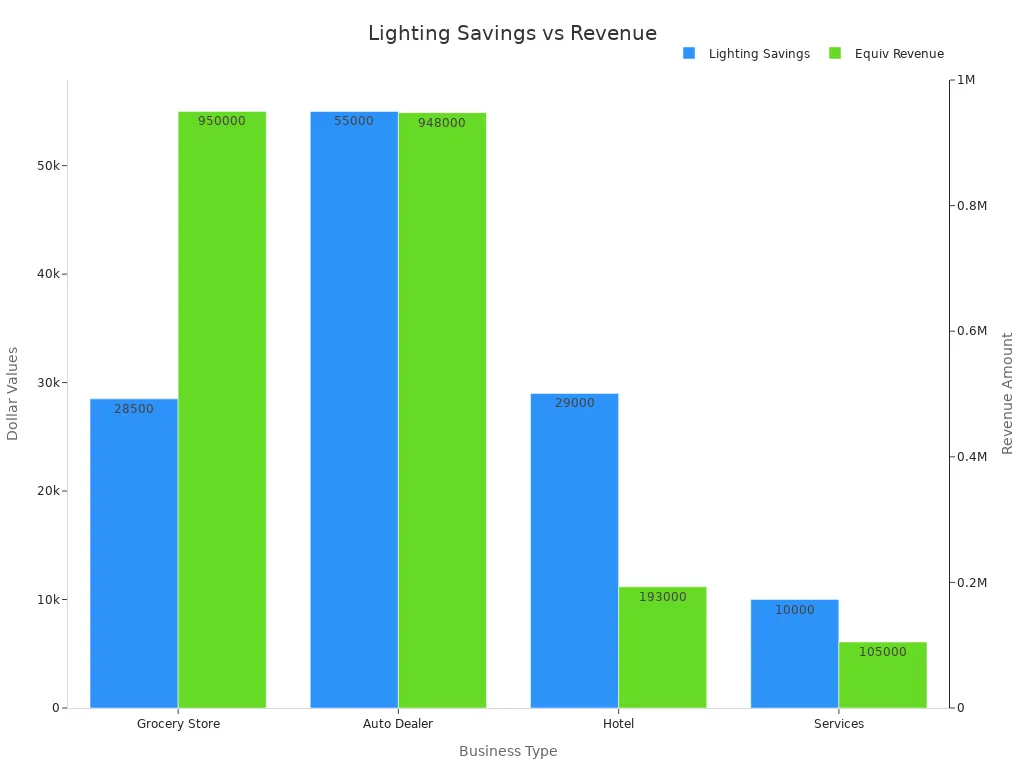

How much money can a business save by using LED lighting?

Businesses can save up to 60% on lighting costs each year. LED lamps use less power and do not need to be changed often. Many companies get their money back in under three years.

Are LED lamps safer than traditional lights?

Yes. LED lamps do not have mercury or other dangerous stuff inside. They stay cooler, so burns and fires are less likely. Workers do not have to climb ladders as much, so it is safer.

Can LED lamps work in cold or dusty environments?

LED lamps work well in very hot or cold places. They also do well in dusty areas. These lamps can handle shaking and wetness. This makes them great for warehouses, factories, and outside.