Choosing the Right Industrial LED Light: Key Specifications and Features Explained

When you pick an industrial led light, look at the main features. These features help with how well the light works and saves money. Lumen output, wattage, color temperature, beam angle, and energy efficiency are important. They change how bright and useful your lights are. For example, a 10W Led Light can give 480 lumens. Some industrial lights can go over 80,000 lumens. You can save up to 75% on energy. The lights can last for 35,000 hours, so you do not need to fix them often. The size and shape of your building are important too. Pick the right light and type for your space. Good industrial led lighting can save money and help people work better. Always read the Product details and check the About Us and Home page before you buy.

Key Takeaways

Look at key specs like lumen output, wattage, color temperature, beam angle, CRI, energy efficiency, and durability to find the best industrial LED light.

Measure your building’s size, ceiling height, and layout. This helps you pick lights that fit your space and work needs safely and well.

Pick LED UFO high bay lights for high ceilings and tough places. Use linear LED high bay lights for wide, lower spaces to save energy.

Use features like dimming controls, sensors, and smart integration. These help save energy, make people comfortable, and make lighting easier to use.

Think about the total cost, including energy savings and maintenance. Look for long warranties to make sure your LED lights last and save money over time.

Key Specs for Industrial LED Lighting

When you pick an industrial LED light, you need to know the main specs. Each spec changes how the light works, how much it costs, and how your building runs. Here is what each important spec means:

Lumen Output

Lumen output tells you how much light you get from a fixture. In big spaces, you need enough lumens to see well and stay safe. More lumens means more brightness, but it can also use more energy and cost more. If you make the lumen output higher by using more power, the light may get hotter and not last as long.

Lumen output depends on how much current and heat the LED gets. Using less current makes LEDs work better, but you might need more LEDs to get enough light.

In industrial places, you often need between 10,000 and 80,000 lumens for each light. This depends on how big the area is and how high the ceiling is.

Always look at the total lumens on the label, not just the wattage.

Tip: Compare how many lumens each light gives, not just the wattage. More lumens for each watt means the light is more efficient.

Making the light brighter can sometimes make it less efficient because of heat. Good cooling helps keep the light bright and efficient.

Wattage

Wattage shows how much power your LED light uses. Lower wattage with high lumens means the light saves more energy. You want lights that are bright but do not use too much power.

Luminous efficiency is how many lumens you get for each watt. For example, if a light gives 20,000 lumens at 200 watts, it is 100 lumens per watt.

High wattage does not always mean the light is brighter. Look for the most lumens for each watt.

Power factor is important too. If the power factor is low, your energy bill can go up even if the wattage is low.

Note: Always check both the wattage and the efficiency. This helps you pick the best light for your money.

Color Temperature

Color temperature, measured in Kelvin, changes how the light looks and how people feel. Most industrial LED lights use color temperatures from 4000K to 6500K.

Higher color temperatures, above 5000K, can help people stay awake and focus. Blue light can make people more alert and help them work better.

Lower color temperatures, around 4000K, feel warmer and can make people feel more relaxed, but sometimes sleepy.

The best color temperature depends on what kind of work you do. For detailed work, higher color temperatures help you see better.

Tip: Pick the color temperature that fits the work and mood you want in your building.

Beam Angle

Beam angle shows how wide the light spreads from the fixture. It is measured in degrees. The right beam angle helps you light up the space evenly.

Narrow beam angles, like 30° to 60°, shine light on small spots. These are good for tall shelves or close-up work.

Wide beam angles, like 90° to 120°, spread light over big areas. These work best for open rooms or assembly lines.

The right beam angle can help you use fewer lights and save money on setup.

Tip: Match the beam angle to your ceiling height and room shape. Use wide angles for big spaces and narrow angles for focused work.

CRI

CRI, or Color Rendering Index, shows how well a light shows colors compared to sunlight. A higher CRI means colors look more real and clear.

Industrial LED lights with a CRI over 80 are good for most jobs. For work that needs perfect color, like checking products, pick a CRI over 90.

The International Commission on Illumination sets the rules for CRI tests. Newer tests like TM-30-20 give even more details about color.

High CRI lights help people see details and spot dangers.

Note: Always check the CRI, especially if you need to match colors or check for safety.

Energy Efficiency

Energy efficiency is a big reason to use industrial LED lights. Efficient lights use less power to make the same or more light.

Industrial LED lights can save up to 75% energy compared to old lights. This means lower bills and less harm to the planet.

Look for lights with lots of lumens per watt and a good power factor.

Efficient lights also make less heat, which can help you save on cooling.

Lighting Class / Scenario | Notes | |

|---|---|---|

M3 (LED vs HPS) | ~31% | Photometric equivalence ensured |

M3 (with dimming) | ~50% | Includes dimming scenarios |

Retrofit project | Up to 84% | With dimming applied |

Tip: Pick lights with high energy efficiency to save money and help the environment.

Durability

Durability means how long your LED light lasts and how well it handles tough places. Long-lasting lights mean you do not have to fix or replace them often.

Industrial LED lights can last 50,000 to 100,000 hours. This is much longer than old lights.

Good durability comes from strong parts, good cooling, and quality drivers.

Tests show that longer-lasting LEDs are better for the environment because you throw away fewer lights.

Note: Look for lights with long warranties and tested lifespans. Check if the product meets standards for durability, like rated lifetimes and special tests.

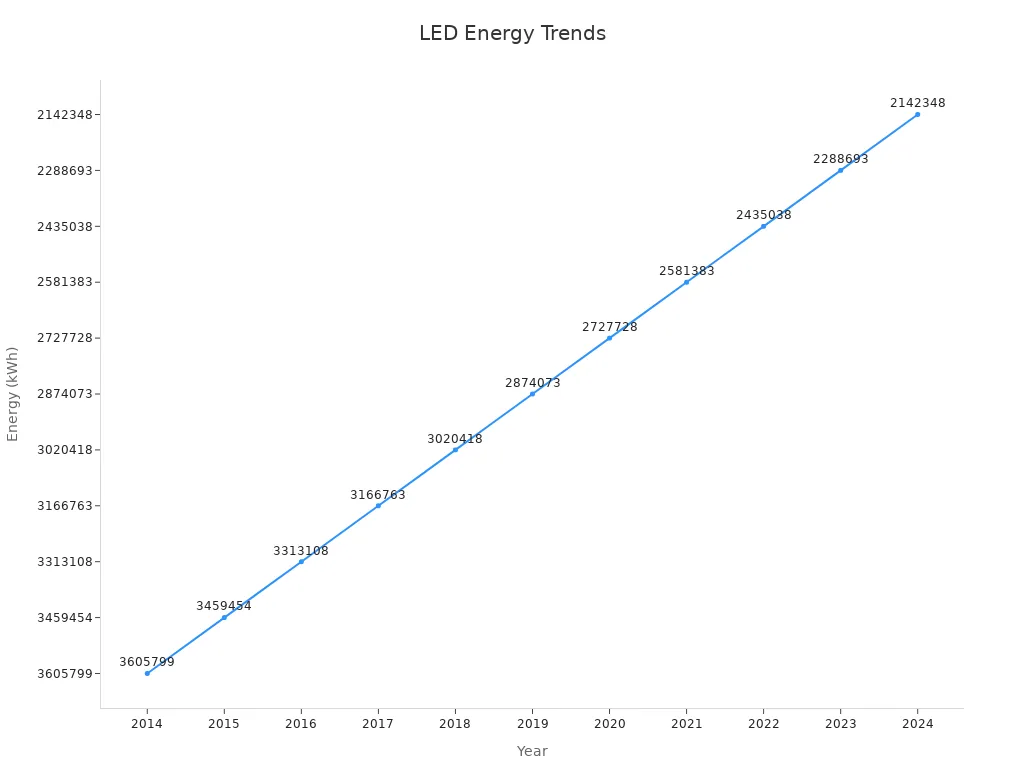

This chart shows that energy use goes down as more places use efficient lighting.

When you compare industrial LED lights, always check these specs: lumen output, wattage, color temperature, beam angle, CRI, energy efficiency, and durability. These things help you pick the best light, save money, and get better lighting. The right specs make your building safer, brighter, and more efficient.

Assessing Your Space

You should look at your building before picking lights. The size, ceiling height, and layout all matter. These things help you choose the best lights for safety and work.

Facility Size

First, measure how big your building is. The bigger the space, the more lights you need. Each light must give enough lumens to reach every spot. Big rooms need more lumens to be bright everywhere. For example, a classroom that is 1,000 square feet may need 15 lights. Each light should give 3,000 to 4,000 lumens. This helps you get the right amount of light. Warehouses need different numbers of lights and lumens. It depends on what jobs people do there.

Tip: Check the foot-candle levels for your tasks. Use this chart to help you plan:

Industrial Task/Area | Recommended Foot Candles (fc) |

|---|---|

Coarse Material Processing | 10 |

Fine Material Processing | 50-100 |

Simple Assembly | 15-60 |

Exacting Assembly and Inspection | 150-600 |

General Food Processing | 75 |

Warehouse (Inactive Area) | 5-10 |

Warehouse (Active Area) | 10-60 |

If you match your lumens to these numbers, your lights will be safe and help people work well.

Ceiling Height

Ceiling height is very important for lighting. Low ceilings, under 20 feet, need LED low bay or linear lights. High ceilings, from 20 to 40 feet, need LED high bay lights. These lights need the right beam angle and more lumens. Very high ceilings, over 40 feet, need high mast lights. These give enough light for tall spaces.

Most places need 200-300 lux for normal work. For detailed jobs, you may need up to 1,500 lux. The type of light and how bright it is depends on your ceiling and what you do.

Layout

The way your building is set up changes how you use lights. Open rooms need wide beam angles and lots of lumens. Places with aisles or shelves need focused lights with narrow beam angles. Machines or racks can block light and make shadows. You should plan where to put lights to stop this.

Lighting software can help you see how your lights will work. It lets you test different ideas and make sure every area is bright enough.

Note: Always follow OSHA and IESNA rules for lighting. This keeps your building safe and your lights working well.

Choosing LED High Bay Lights

LED UFO High Bay Lights

You often see led ufo high bay lights in factories, warehouses, and gymnasiums. These led high bay lights have a round, compact shape that looks like a UFO. This design helps them last longer and focus light where you need it most. You can use them in places with high ceilings, usually between 20 and 40 feet. The strong aluminum body keeps them cool and working well.

Here is a table to help you compare led ufo high bay lights with other types:

Specification | UFO LED High Bay Lights (Apollo Series) | Other High Bay Types (e.g., HID) |

|---|---|---|

Design | Circular, compact | Bulkier, often linear |

Wattage Range | 100W–360W | Higher energy use |

Lumen Output | Up to 43,887 lumens | Lower lumens per watt |

Energy Efficiency | Up to 70% savings | Less efficient |

Lifespan | 50,000 hours or more | Shorter lifespan |

CRI | Up to 90 | Up to 80 |

Protection Rating | IP65 (wet location safe) | Often lower |

Dimmable | Yes (0-10V, DALI) | Rare |

You get many benefits with led ufo high bay lights:

They use less energy than old lights but give more brightness.

They last up to 50,000 hours, so you change them less often.

They turn on instantly and give even lighting.

They work well in tough places, like wet or dusty areas.

You can dim them to save even more energy.

You can choose from different wattages, like 100W, 150W, or 200W. These led high bay lights give you 145-155 lumens per watt, which means you get more light for less power. The IP65 rating keeps them safe outdoors or in harsh indoor spaces. You can mount them in many ways, such as with a yoke or pendant.

Linear LED High Bay Lights

Linear led high bay lights look like long panels. You often use them in big rooms with lower ceilings, like workshops or storage areas. These led high bay lights spread light over a wide area, making them great for aisles or open spaces.

Linear led high bay lights usually come with 0-10V dimming. You can add sensors for daylight or motion, which helps you save energy. These lights work best in dry, indoor places. They replace old tube lights, like T5 or T8 fixtures, and give you better lighting with less power.

Here are some key points about linear led high bay lights:

They give a wide beam, so you need fewer fixtures for large spaces.

You can mount them with cables, pendants, or directly to the ceiling.

They work well for ceilings up to 30 feet.

You get 135-140 lumens per watt, which means good energy savings.

They are not as tough as led ufo high bay lights, so use them where you do not need high impact or wet ratings.

Both led ufo high bay lights and linear led high bay lights use advanced led technology. You get better energy efficiency, longer life, and less heat. High powered high bays give you strong, bright lighting for any industrial job. Choose the type that fits your space and needs.

Advanced Lighting Features

Today’s industrial lighting has special features that help you save energy and keep people safe. These features also make your building smarter. You can pick from many lighting options to fit what you need. Here are three key features: dimming controls, sensors, and smart integration.

Dimming Controls

Dimming controls let you change how bright your lights are. You can make the lights dimmer when you do not need them as bright. This helps you use less energy and spend less money. Studies show that using dimming controls with LED lights can lower energy use by up to 87% each year. Some tests found savings as high as 94% during the day. Dimming controls also help your workspace feel better. You can set times for lights to dim at night or when fewer people are there.

Tip: Use dimming controls to set the right light for each job. This helps people work better and feel more comfortable.

Sensors

Sensors are smart tools that make your lighting even better. They turn lights on or off when they sense movement or see daylight. There are different kinds of sensors for industrial spaces:

Sensor Type | How It Works | Best Use |

|---|---|---|

Uses sound waves to find movement | Corridors, large rooms | |

Passive Infrared | Senses changes in body heat | Offices, small areas |

Dual Technology | Uses both for better results | Open spaces, warehouses |

Sensors help you save energy by turning lights off when no one is around. They also keep work areas bright when people are there. You can set up sensors for different parts of your building, like aisles or storage rooms, to save even more energy.

Smart Integration

Smart integration lets you control all your lights from one place. You can use your phone or computer to do this. Smart lighting lets you set up wireless networks, change lights for different jobs, and see how much energy you use. Some systems can connect to Wi-Fi, cameras, or safety alarms. For example, one big factory changed old lights to smart LED lights and saved enough energy to power over 200 homes for a year.

Smart features help you handle emergencies, keep your building safe, and run things better. You can use sensors to watch equipment or check air quality. Many factories get their money back in just a few years after switching to smart lighting.

Note: Smart integration makes your lighting easy to change and ready for the future. You can add new features when you need them.

Budget and Warranty

Cost Analysis

When you plan lighting for your building, think about cost now and later. LED lighting costs more at first than old lights. But you save money as time goes on. The LED lighting market is getting bigger every year. In 2024, experts say it will be worth over $88 billion. By 2030, it could reach $134 billion. This means more companies are picking LED lighting. They want better lights and lower bills.

LED lighting uses less power and lasts longer. This means you pay less for energy. Some businesses save up to 75% on their bills. These savings keep adding up each year. You also do not have to change bulbs as much. This saves money on repairs. Many governments help pay for LED lighting. This makes it even cheaper for you.

When you look at different lights, check these things:

How much you pay to buy the lights

How much energy you will save over time

How much it costs to fix or replace parts

What kind of warranty you get

A table can help you see the differences:

Factor | LED Lighting | Traditional Lighting |

|---|---|---|

Upfront Cost | Higher | Lower |

Energy Savings | High | Low |

Lifespan | Long | Short |

Maintenance Needed | Low | High |

Tip: Look at the total cost, not just the price you pay first. LED lighting can save you money with lower bills and fewer repairs.

Warranty

A good warranty keeps your lighting safe if something goes wrong. Most industrial LED lights have warranties from 3 to 10 years. A longer warranty means the company trusts its lights. Some top brands give 10 years of coverage for lights that last 100,000 hours.

Warranties cover problems from how the light was made. They do not cover damage from bad setup or using the light wrong. Companies test their lights with special rules like IES LM-80 and TM-21. They use strong parts and good cooling to make sure the lights last a long time.

Look for these things in a warranty:

How long the warranty lasts and when it starts and ends

What you need to do to make a claim

Proof that you set up the lights the right way

If the warranty covers important parts like drivers and LED chips

Note: A longer warranty means you have less to worry about. It also means the lights should last as long as promised.

Making the Right Choice

Selection Checklist

You want the best results when you choose led ufo high bay lights or other led high bay lights for your facility. A clear checklist helps you make smart choices. Use this guide to check each important step:

Measure your space

Find the size, ceiling height, and layout. This helps you know how many led ufo high bay lights or led high bay lights you need.Set your lighting goals

Decide how bright you want your space. Check the lumen output and color temperature for your tasks.Compare energy use

Look at the power consumption of each led ufo high bay lights model. Pick the ones that save the most energy.Check durability and safety

Make sure your led high bay lights have strong parts, good cooling, and a long warranty.Review advanced features

Choose led ufo high bay lights with dimming, sensors, or smart controls if you want more savings and flexibility.Follow standards

Make sure your lighting meets safety and energy rules. This keeps your building safe and efficient.

Tip: Many engineers use a checklist like this to make sure they do not miss any key step. This method helps you get the right led ufo high bay lights for your needs.

Summary Table

You can compare led ufo high bay lights and other led high bay lights using a summary table. This table shows how different fixtures perform in real settings. It helps you see which lighting option works best for your space.

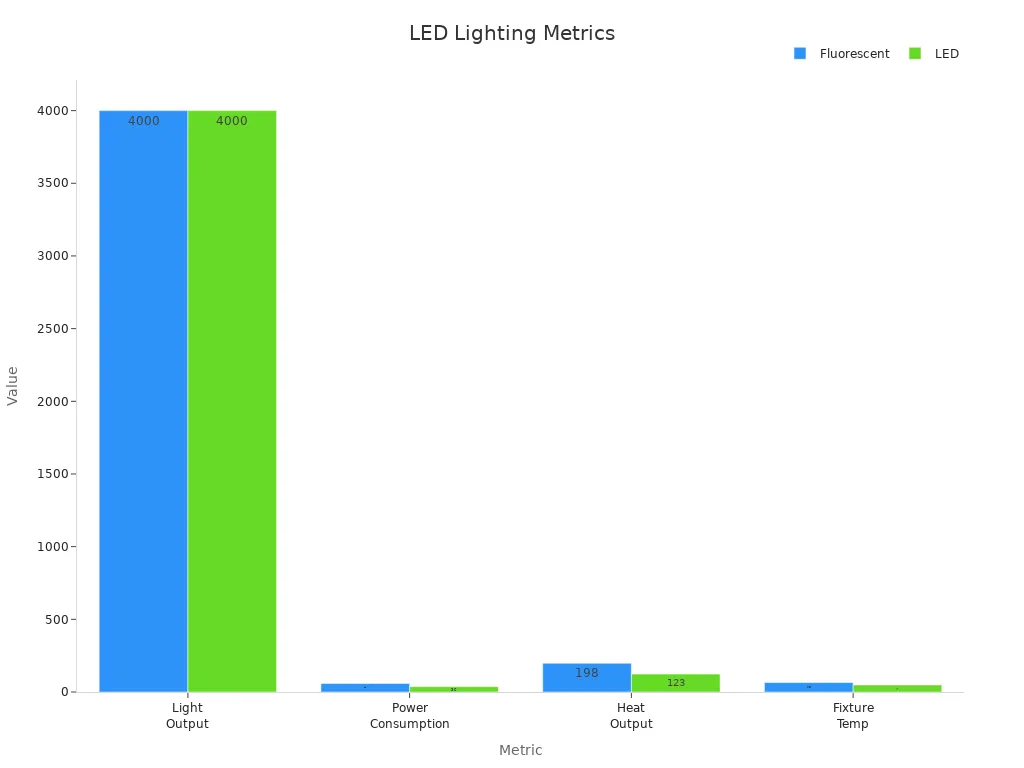

Metric | Fluorescent Fixture (58W) | LED High Bay Lights (36W) |

|---|---|---|

Light Output | 4000 lumens | 4000 lumens |

Power Consumption | 58 watts | 36 watts |

Heat Output | 198 BTU/hr | 123 BTU/hr |

Fixture Temperature | ~65°C | ~48°C |

Cooling System Impact | High | Low |

You can see that led ufo high bay lights and led high bay lights use less power and make less heat. This means your cooling system works less, and you save money. You also get the same or better lighting.

When you use this table and checklist, you make better choices. You get led ufo high bay lights or led high bay lights that fit your space, save energy, and last longer. Good lighting makes your facility safer and more productive.

Picking the right industrial LED lighting helps you save money and energy. It also makes your building safer and more efficient. When your lights fit your building’s needs, workers feel happier and safer. Fewer accidents happen, and you use less energy. Use the checklist and table to compare your lighting choices and make good decisions.

To get the best results, look at your current lights, plan for repairs, and talk to a lighting expert. The right lights can cut costs by up to 75% and help your business grow for a long time.

FAQ

What is the best color temperature for industrial LED lights?

You should choose 5000K to 6500K for most industrial spaces. This range gives you bright, clear light. It helps workers see details and stay alert. For areas where comfort matters, 4000K works well.

How do I know how many LED lights I need?

Measure your space and check the recommended foot-candle levels for your tasks. Use a lighting calculator or ask a lighting expert. You want even light across all work areas.

Tip: Always check the lumen output of each fixture before you buy.

Can LED high bay lights save money on energy bills?

Yes, LED high bay lights use less power than old lights. You can save up to 75% on energy costs. They also last longer, so you spend less on replacements and repairs.

Do I need special wiring for LED industrial lights?

Most LED lights work with standard wiring. You may need new dimmer switches or controls if you want advanced features. Always follow the manufacturer's instructions for safe installation.

Feature | Standard Wiring | Special Controls Needed |

|---|---|---|

Basic Lighting | ✅ | ❌ |

Dimming/Smart | ❌ | ✅ |

See Also

Choosing LED High Bay Lights: Uses, Advantages, And Tips

Energy Efficient LED Indoor Lighting Types And Their Uses

Comparing UFO, Linear, And Round LED High Bay Lamps