Industrial LED Lighting ROI and its Long-Term Savings and Performance Benefits

Industrial LED Lighting gives a good return on investment. It helps save money for a long time. It also works well and lasts long. Facilities use up to 75% less energy than old lights. LEDs can last 50,000 hours or even longer. This is much longer than older lights. For example, one place used 291,233 kWh less energy each year. They saved over $400 every year by changing bulbs. These savings lower both running and fixing costs. Businesses that want good lighting can look at the right Product. They can learn more on the Home page. They can also visit About Us for expert help with Led Light upgrades.

Key Takeaways

Industrial LED lighting uses up to 75% less energy. This helps save money on electricity bills fast. LEDs last much longer than old bulbs. This means you spend less on fixing lights and have less downtime. LEDs give better light quality. This helps keep workers safe and comfortable. It also helps them work better. LEDs make less heat. This lowers cooling costs and helps HVAC systems work less. Many rebates and payment plans make LED upgrades cheaper. These options help you get your money back faster.

Energy Savings

Consumption Comparison

Industrial LED Lighting uses much less energy than old lights. Studies show LEDs are 18% to 44% more efficient than T8 fluorescent lamps. The U.S. Department of Energy says LEDs use at least 75% less energy than incandescent bulbs. LEDs also last 25 times longer. In Japan, homes used almost 2% less electricity after switching to LEDs. If all lamps were changed, savings could reach nearly 7%. These facts show LEDs save more energy than incandescent and fluorescent lights.

When facilities switch to Industrial LED Lighting, they can cut lighting energy use by half or more. This means lower utility bills and less stress on electrical systems.

Many real-world projects prove these savings:

Changing 193,045 streetlights to LEDs saved about 70% energy each year.

A retrofit in Palermo saved up to 84% energy with dimming controls.

Coventry used 44% less electricity over 20 years by switching 29,701 streetlights to LEDs.

Using smart controls with LED upgrades can save even more, sometimes up to 66%.

Savings Calculations

Facility managers can use a simple formula to guess yearly energy savings:

Annual kWh Savings = (Existing Watts - LED Watts) × Hours of Operation × Number of Fixtures ÷ 1,000

For example, a plant replaces 100 metal halide fixtures (458W each) with 150W LED fixtures. If the lights run 4,380 hours a year, they save about 134,904 kWh each year. With electricity at $0.12 per kWh, this saves $16,188 every year.

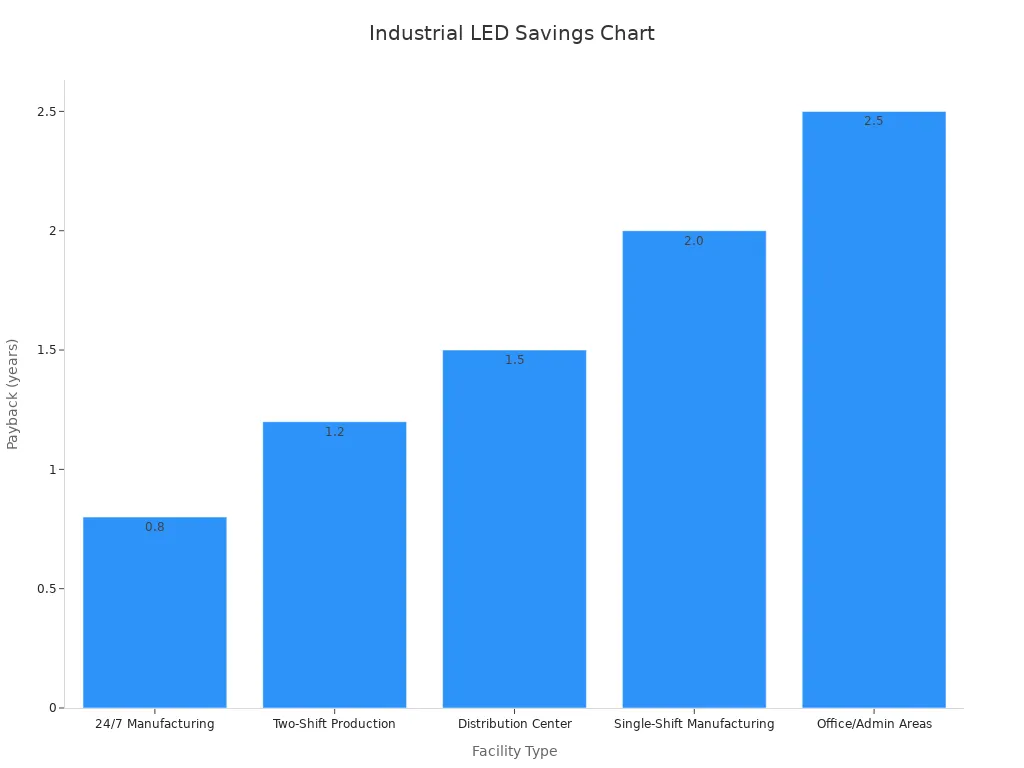

The payback time for Industrial LED Lighting depends on the facility and how much it is used. The table below shows normal payback times:

Facility Type | Operating Hours | Typical Payback (years) | Best-Case Payback (years) |

|---|---|---|---|

24/7 Manufacturing | 8,760 | 1.2 - 2.0 | 0.8 |

Two-Shift Production | 5,000 | 1.8 - 2.5 | 1.2 |

Distribution Center | 4,380 | 2.0 - 3.0 | 1.5 |

Single-Shift Manufacturing | 2,500 | 3.0 - 4.0 | 2.0 |

Office/Admin Areas | 2,000 | 3.5 - 5.0 | 2.5 |

Note: Facilities that run longer hours get their money back from LED upgrades faster.

Other benefits help save even more money:

HVAC costs go down because LEDs make less heat.

Less maintenance and fewer spare parts are needed.

Fewer utility penalties because of better power factor.

Better lighting helps people work safer and faster.

Case Examples

Many factories and companies have already saved a lot with LEDs.

The Port of Houston changed a big warehouse from high-pressure sodium to LEDs.

An OSB plant that runs all day and night switched to LEDs for nonstop savings.

A chemical plant shop got better lighting and paid less with LEDs.

A refrigeration company and some retail chains also saved a lot of energy and money.

Here is an example from a manufacturing company:

Metric | Before Retrofit | After Retrofit | Savings |

|---|---|---|---|

Energy Consumption | 1,500,000 kWh/year | 750,000 kWh/year | |

Energy Costs | $150,000/year | $75,000/year | $75,000 saved |

Maintenance Costs | $20,000/year | $5,000/year | $15,000 saved |

This project paid for itself in less than two years. Other projects, like a nationwide LED change for a global shipping company, saved millions each year in energy and running costs.

These real-life examples show that Industrial LED Lighting gives real energy savings and quick payback for many kinds of facilities.

Maintenance and Operational Costs

Longevity

Industrial LED Lighting lasts much longer than old lights. Most LEDs work for over 50,000 hours. Older bulbs only last 10,000 to 20,000 hours. This means you do not need to replace LEDs as often. You also spend less time fixing them. The industry uses lumen depreciation to check LED life. LEDs do not burn out fast. They slowly get dimmer over time. The L70 rating tells how long an LED keeps 70% of its light. Many industrial LEDs reach L70 at 50,000 hours or more. Tests like IES LM-80 and TM-21 help prove these numbers. These tests show how well LEDs keep their brightness.

Metric | Definition | Example | Application Context |

|---|---|---|---|

L70 Lifetime | Time until LED lumen output decays to 70% of original brightness, marking end of useful life. | L70 at 50,000 hours | Standard lifetime estimate for LEDs |

LxxByy Report | Minimum luminous flux maintained (L) and percentage of LEDs meeting that flux (B) over time. | L80B10: 80% flux at 50,000 hrs with 90% LEDs meeting it | Used for reliability in different applications |

The Department of Energy says to use L70 and similar ratings to judge LED life. This gives a better idea of how long LEDs will give good light.

Maintenance Reduction

LEDs last longer, so you do not need to change them often. This saves money on labor and parts. Workers spend less time changing bulbs. Companies can save up to 80% on replacement costs. One big retail chain saved over $100 million each year. They also used 55% less energy for lighting. Smart controls like motion sensors help save even more. These controls can cut energy costs by up to 60%. They turn off lights when no one is there. This helps LEDs last longer.

Evidence Aspect | Statistic / Data Point | Impact on Maintenance and Operational Costs |

|---|---|---|

LED Lifespan | Over 50,000 hours vs. 10,000-20,000 hours (traditional bulbs) | Up to 80% reduction in replacement costs, fewer maintenance cycles |

Labor and Maintenance Savings | Thousands of dollars saved annually due to less frequent replacements and reduced labor | Lower operational costs and minimized downtime |

Smart Controls (Motion Sensors) | Energy costs cut by up to 60% through adaptive lighting | Further operational cost reduction via optimized energy use |

Case Study (Retail Chain) | 55%-60% reduction in energy consumption; annual savings over USD 100 million | Demonstrates large-scale operational cost savings |

Facilities that use Industrial LED Lighting spend less on repairs. They also have fewer problems with lights. This means less downtime and fewer work delays.

Operational Impact

Switching to LEDs helps daily work in many ways. LEDs use less energy, so bills are lower. They make less heat, so cooling systems work less. In factories, better lighting makes work safer. Workers can see better. One factory used 60% less energy after switching to LEDs. They also had fewer accidents. In plant growing, LED grow lights use about 50% less energy than high-pressure sodium lamps. This saves money and cuts waste from old bulbs.

Some LED lamps have low power factors. This can cause extra energy charges. These charges may raise yearly costs if not fixed. Facilities should pick LED products with high power factors to avoid this.

LEDs give a lot of light for each unit of energy. They often reach 105 lumens per watt. This means you get more light for your money.

Evidence Aspect | Statistic / Data Point | Impact on Maintenance and Operational Costs |

|---|---|---|

Energy Savings | Up to 75% savings in lighting-related energy costs (Deloitte) | Major reduction in energy expenses |

Manufacturing Facility Upgrade | 60% decrease in energy usage; improved safety and efficiency | Reduced operational disruptions and costs |

Government Incentives | Tax credits and rebates improve payback period and ROI | Lower upfront and operational costs |

By picking good LED products, facility managers can save more money. They can also make daily work better.

Additional Savings

Cooling Costs

Industrial LED lighting makes less heat than old lights. This means air conditioning does not work as hard. In big buildings, saving one kWh in lighting can save 0.4 kWh in HVAC energy. Studies show LEDs can cut HVAC energy use by 40% or more. This is true in places that need a lot of cooling. LEDs do not give off much infrared or ultraviolet radiation. So, less heat gets into work areas. This lowers cooling bills and helps HVAC systems last longer. Buildings in hot places or with many lights get the most savings.

Tip: Less heat from LEDs means cooling systems work less. This saves money in more than one way.

Incentives and Rebates

Many states and power companies give rebates for LED upgrades. These rebates help pay for new lights. For example, TVA EnergyRight gives $4 for each LED tube and $22 for each LED panel. Some states, like California and Colorado, give bigger rebates to meet new rules. Rebates may need pre-approval and can pay for up to 70% of materials. The table below shows some rebate programs:

State | Program Name | Example Rebate (2024-2025) |

|---|---|---|

Tennessee | TVA EnergyRight | $4 per LED tube, $22 per panel |

California | Lighting Incentives Program | Varies by fixture and compliance |

Vermont | LED Retrofit Rebate Program | Reduced for basic tubes |

Note: Rebates are higher for smart controls like sensors. These can help save up to 47% more energy.

Financing Options

Financing helps more businesses get LED lighting. PACE financing pays for all costs up front. Payments are fixed and last a long time. Energy savings can be bigger than the payments. Some companies let you pay only what you save on your bill. For example, if your bill drops from $2,000 to $600, you pay the $1,400 difference. Landlords can also handle the upgrade and payments. Tenants then get lower bills without paying up front. These plans help businesses get their money back fast, sometimes in less than 18 months. They also help cut repair and cooling costs.

Industrial LED Lighting Performance

Lighting Quality

Industrial LED Lighting gives bright, clear light. It meets tough rules for quality. LEDs make more light for each watt than old lamps. This means they are brighter but use less energy. Their high Color Rendering Index helps people see colors right. This is important for jobs that need careful work. The light spreads out evenly. This cuts down on glare and shadows. Work areas feel safer and more comfortable. Many LED fixtures have IP65 or higher ratings. This means they keep out dust and water. They work well even in rough places. They follow rules like IEC, UL, and IES. This shows they are safe and reliable. The table below lists good lighting levels for different jobs:

Industrial Task | Recommended Foot Candles (fc) |

|---|---|

Fine Material Processing | 50 |

Difficult Assembly | 50-200 |

Warehousing – Active – Small Items | 15-60 |

Maintenance and Shop Areas | 50 |

Cold Storage | 10-30 |

Note: Good lighting helps keep workers safe and helps them do their jobs better.

Productivity

LED lighting helps people work better. It gives bright, even light. This makes it easier to see details. Workers get less tired and their eyes do not hurt as much. They can finish jobs faster and make fewer mistakes. Studies show that better lighting can cut accidents by half. Sometimes, work gets done up to 30% faster with LEDs. LEDs turn on right away. There is no wait after a power outage. Smart controls like dimmers and motion sensors help too. They let you change the light for different jobs. This keeps workers focused and comfortable all day.

Bright, even light helps stop mistakes.

Lights turn on fast so work does not stop.

You can change the light for different jobs and times.

Safety

LEDs make work safer. They give steady, clear light. This helps workers see dangers quickly. Even light means no dark spots or glare. This lowers the chance of trips and falls. LEDs are like daylight, so eyes do not get tired. Workers stay alert. Parking lots and building edges are brighter. This helps stop crime and keeps people safe. LEDs meet OSHA lighting rules. This means the workplace is safer.

Bright, clear light lowers accidents at work.

Even light helps workers spot dangers in busy places.

Good lighting helps workers stay focused and react fast.

Tip: Switching to LED lighting saves energy. It also makes work safer and helps people get more done.

Sustainability Benefits

Carbon Footprint

Industrial LED lighting helps buildings lower their carbon footprint. LEDs use much less energy than old lights. They turn up to 95% of energy into light. Only a little energy is lost as heat. This means less electricity is needed. Power plants make fewer greenhouse gases. For example, one incandescent bulb can make about 4,500 pounds of CO₂ each year. An LED bulb makes only 451 pounds. In 2017, LED lighting helped stop 570 million tons of CO₂ from being made. That is like turning off 162 coal power plants. LEDs last a long time—up to 100,000 hours. This means you do not need to replace them often. Less waste is made and fewer new bulbs are needed. Buildings that use LEDs also use less HVAC energy because LEDs stay cooler.

When companies pick LEDs, they help fight climate change. They also lower their impact on the environment.

Green Standards

Industrial LED lighting helps meet green building standards. Many groups want certifications like LEED or follow ISO 14044 rules. LED products help by using less energy and lasting longer. They do not have mercury and do not give off UV rays. This makes them safer for people and the earth. Reports show there are tax breaks, like the EPAct179 deduction, for using efficient lighting. These tax breaks help companies save money. They also make more companies want to use green lights. LED lighting helps companies follow local and national energy rules.

Green Standard | How LEDs Help Meet It |

|---|---|

LEED Certification | Energy savings, low toxicity |

ISO 14044 | Life cycle assessment compliance |

EPAct179 | Tax deductions for efficiency |

Social Responsibility

Switching to LED lighting shows a company cares about social responsibility. Companies like Brookfield Properties use LED upgrades as part of their green goals. They put in new lights in garages, stairs, and work areas to save energy. This also helps the environment. These projects often include surveys and learning programs for tenants. This gets everyone involved in being green. LED lighting also makes working conditions better by giving good light and making places safer. Studies show that LED upgrades can help the economy and bring good changes to many people.

Companies that use LED lighting set a good example. They show they care about people, the community, and the planet.

Industrial LED Lighting helps save money and works well. Buildings pay less for energy and need fewer repairs. Safety gets better for everyone. Groups can check how well they are doing by looking at ROI, money saved, and how much work gets done. The table below shows what different groups can do and what they get:

Sector | Actionable Step | Key Benefit |

|---|---|---|

Municipalities | Upgrade streetlights | 40-60% cost reduction |

Government | Retrofit buildings | $100,000+ annual savings |

Universities | Campus-wide LED upgrades | Up to 75% energy savings |

Facility managers should look at their lights now. They can get an energy check or talk to an LED expert. Buying LED lighting is a smart choice for the future. It helps any building last longer and work better.

FAQ

How long does it take to see ROI from industrial LED lighting?

Most places get their money back in 1 to 3 years. Sites that use lights all day and night save money faster. This is because they use more energy and need more repairs.

Do LEDs require special maintenance compared to traditional lights?

LEDs do not need much care. They last a long time and do not break often. Workers do not have to change bulbs or fix lights as much. This saves time and money for the team.

Can LED lighting improve workplace safety?

Yes, LEDs make work areas brighter and clearer. Workers can spot dangers more easily. There are fewer dark spots and less glare. This helps stop accidents. Many companies have seen fewer injuries after using LEDs.

Are there financial incentives for switching to LED lighting?

Many states and power companies give rebates or tax credits for LED upgrades. These help pay for new lights and make payback faster. Facility managers should look for local programs before starting a project.

See Also

Energy Efficient LED Lighting Solutions And Uses For Interiors

Different Indoor LED Signage Options And Advantages For Businesses