LED High Bay Lighting ROI: Calculating Energy Savings and Payback Period

Facilities that use led high bay lighting often pay less for energy and maintenance. For example, a 100W led light costs only $3.60 each month to run. A 300W led light costs about $10.80 each month. You can see the costs in the table below:

LED Wattage | Monthly Energy Cost (USD) |

|---|---|

100W | 3.60 |

150W | 5.40 |

200W | 7.20 |

250W | 9.00 |

300W | 10.80 |

Led lighting uses less power. It also means you do not have to change bulbs as often. This saves money on labor too. These savings help businesses get more value from each Led Light upgrade. Many groups, whether looking for Home, Product, or About Us solutions, get these benefits.

Key Takeaways

LED high bay lighting helps save money. It uses less energy and needs less maintenance. - Calculating ROI lets businesses know if LED upgrades are worth it. It also shows how quickly they get their money back. - Looking at both energy and maintenance savings shows total savings. It also helps find out how long payback takes. - Using lighting controls and getting rebates can help save more money. These steps can also make payback time shorter. - Avoiding mistakes like picking the wrong fixture is important. Good planning keeps ROI high and payback quick.

LED High Bay Lighting ROI

What Is Lighting ROI

Lighting ROI stands for return on investment in lighting projects. It measures how much money a facility saves compared to what it spends on new lighting. When a business upgrades to led high bay lighting, it wants to know if the savings will cover the cost of the upgrade. Lighting ROI gives a clear answer. It uses numbers from energy bills, maintenance costs, and the price of new lights. This calculation helps managers see if led lighting will pay off over time.

A simple formula for lighting ROI looks like this:

ROI = (Total Savings - Total Costs) / Initial Investment x 100

This formula shows the percentage of return. If the number is high, the project brings more value. If the number is low, the project may not be worth the cost.

Why ROI Matters

ROI plays a key role in every led high bay lighting project. Facility managers and business owners use ROI to make smart choices. They want to see if led lighting will save money and improve their bottom line. ROI also helps them compare different lighting options.

ROI is not just about saving money. It also shows how fast a business can recover its investment.

Industry data highlights several reasons why ROI is critical:

ROI quantifies financial benefits and long-term savings, making it easier to justify investments.

Led high bay lighting can cut energy costs by up to 80%, which lowers monthly bills.

Maintenance costs drop because led lighting lasts longer and needs less upkeep.

ROI helps companies build strong business cases, win bids, and plan budgets.

Projects often see payback periods between 3 and 7 years, with some showing ROI values over 200%.

Environmental benefits, like lower carbon footprints, can unlock extra incentives.

A strong ROI means led high bay lighting upgrades can double or even triple the initial investment over time.

Calculating Energy and Maintenance Savings

Gather Lighting Data

Facility managers begin by writing down details about their lights. They count how many fixtures they have. They check the wattage for each fixture. They also see how many hours the lights are on each year. The local electricity rate is important too. All this information helps them make good calculations. To do a led retrofit, managers compare the old lights to the new led lights. They look at how much energy both systems use. They also check how often they need maintenance. This step makes sure the savings are real for their building.

Estimate LED Savings

Next, managers figure out how much energy the new led lights will save. They use a simple formula to help them:

Annual Energy Savings = (Old Wattage - New Wattage) x Hours Used Per Year x Electricity Rate / 1000

This formula tells them how much less energy the new led lights use. For example, if they swap 400W metal halide fixtures for 150W led lights, they save a lot of energy each year. Some places can save up to 80% on energy. These savings are big in large spaces like warehouses or gyms. Managers should always count both energy and maintenance savings. This gives them the real amount they save.

Maintenance Savings

Led lighting does more than lower energy bills. It also cuts down on maintenance costs. Orion Lighting says led high bay fixtures last 50,000 to 100,000 hours. This means they do not need to be replaced as often. Staff spend less time changing bulbs or fixing lights. Many led retrofit projects save money because of this. New led systems can have smart controls and automation. These features mean even less work for staff. When managers add up savings, they include both energy and maintenance savings. This way, they see the total savings from the led retrofit.

Payback Period for LED High Bay Lighting

Project Cost

Project cost is the first thing to think about. Facility managers need to add up the price of new LED high bay fixtures. They also count installation fees and any extra equipment. Sometimes, utility companies give rebates or incentives. These can make the total cost lower. Getting the right project cost helps payback models show real results. Managers should collect all invoices and receipts before they start to figure out payback.

Payback Period Formula

The payback period shows how long it takes to get your money back. The formula is:

Payback Period = Net Project Cost / (Annual Energy Savings + Annual Maintenance Savings)

This formula lets managers compare payback models. It helps them see which choice gives the fastest return. For example, if a warehouse spends $20,000 on LED upgrades and saves $5,000 each year, the payback period is four years. Most payback periods are between two and six years. Rebates can make the payback period shorter by lowering the first cost. Facility teams use this formula to plan budgets and figure out payback.

Factors Affecting Payback

Many things can change the payback for LED high bay lighting. Energy rates, hours of use, and building size all matter. Higher energy costs mean faster payback. More hours of use make yearly savings bigger. Rebates and incentives can lower the first cost and change payback models. Maintenance savings also help payback happen faster. Facility managers should look at all these things before they decide. Checking these factors makes sure payback models match what happens in real life.

Tip: Always add both energy and maintenance savings to payback models for the best results.

Return on Investment Calculation

ROI Formula

Facility managers use a simple formula to check return on investment for LED high bay lighting projects. This formula helps them see how much money the upgrade can save over time. The calculation is:

ROI = (Total savings - Total costs) / Initial investment x 100

This formula adds up all savings, like energy, maintenance, and rebates. By using this method, managers can look at different projects and pick the best one. Studies show this way works well for real lighting upgrades. Many real-life stories prove the regular ROI formula gives good results. Lighting retrofits can cut energy and maintenance costs by as much as 70%. Most payback periods are about two years, which means a 50% return on investment. These facts show the formula is useful and correct.

Example ROI Calculation

A real case from a school shows how a full return on investment calculation works. The project compared a regular fluorescent system to an LED system using several important points:

Metric | Baseline Fluorescent System | LED System |

|---|---|---|

Number of fixtures | 300 | 300 |

Fixture wattage | 128 W | 53 W |

Fixture cost | $62 housing + $10 lamps | $249 per fixture |

Fixture lifespan | 20,000 hours | 50,000 hours |

Daily usage | 12 hours | 12 hours |

Annual usage days | 250 | 250 |

Energy cost | $0.14/kWh | $0.14/kWh |

Labor cost for maintenance | $30/hour | $30/hour |

Labor hours to replace lamps | 4 workers × 25 hours | N/A |

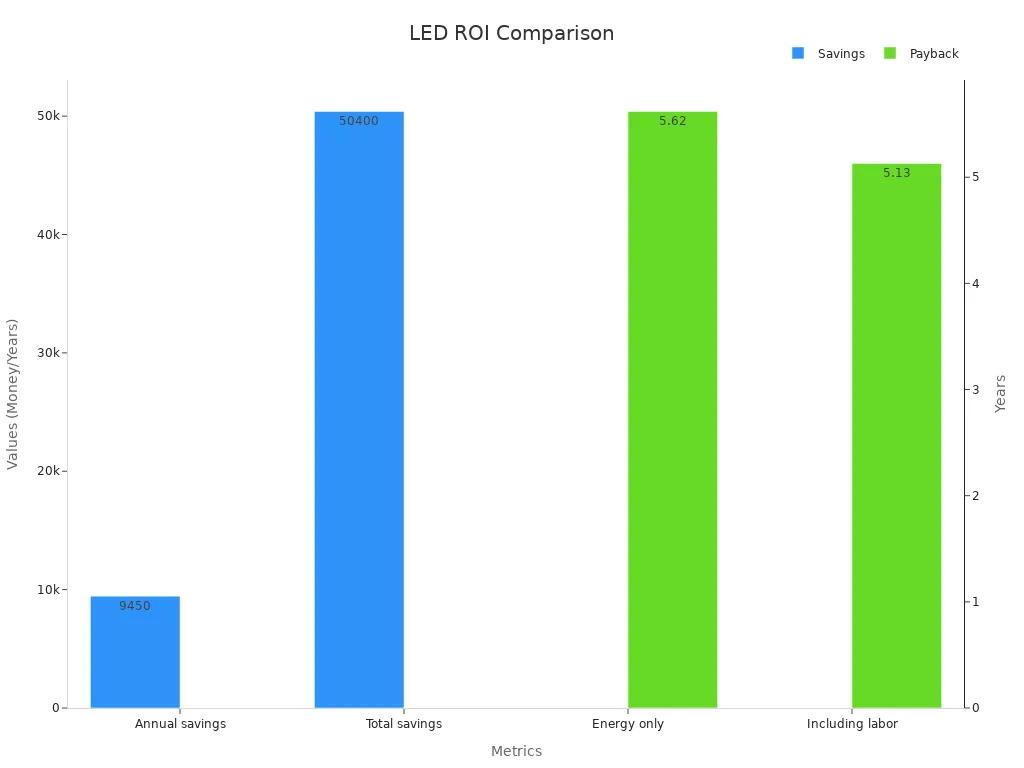

The LED system saved $9,450 in energy each year. When adding maintenance and labor, total savings over 10 years reached $50,400. The payback period from energy savings alone was 5.62 years, with an 18% return on investment. When counting maintenance, the payback period dropped to 5.13 years and the return on investment went up to 19.5%. With energy rebates, the return on investment rose to 25.1%, and the payback period dropped below four years. This example shows why it is important to count all savings and incentives in the calculation.

Interpreting Results

A high return on investment means the lighting project saves a lot of money. Facility managers want a return on investment above 15% to show a project is a good idea. A higher number means faster payback and more savings over time. If the return on investment is low, the project may not save enough money. Managers should always count energy, maintenance, and rebate savings in their math. This way, they get a clear picture of the project’s real value. The net savings from LED upgrades help companies plan budgets and make smart choices. By using the return on investment formula, managers can compare projects and pick the best one.

Tip: Always use the full return on investment formula and add every type of savings for the best results.

Maximizing Lighting ROI

Tips for More Savings

Facility managers can make ROI better and payback faster by using smart steps. Picking energy-saving lighting, like LED lighting, saves a lot of money. The U.S. Department of Energy says LEDs use at least 75% less energy. They also last up to 25 times longer than regular bulbs. This means less wasted light and heat, so bills go down. Choosing ENERGY STAR rated products gives the best results and trust.

Lighting controls help save even more. Timers, dimmers, and occupancy sensors stop lights from being on when not needed. Studies show that using good sensor controls with LEDs can save between 23% and 76% more energy. Shorter times on occupancy sensors do not hurt LED lifespan, unlike old lights. Using occupancy sensors with daylight harvesting can save up to 79%. These ideas make every LED upgrade work better.

Facility teams should look for rebates and special offers. Many utility companies have programs that lower the first cost, so payback is faster. Checking lights often keeps them working well. Outdoor lights with motion sensors and daylight shut-off features save even more money. All these actions help get a higher ROI and faster payback for any LED project.

Tip: Always pick lighting controls that fit the space and use good products for the best results.

Mistakes to Avoid

Some common mistakes can make ROI lower and payback take longer in LED projects. Experts point out these problems:

Buying LED lights that are too weak or too strong for the area.

Picking fixtures with the wrong beam angle or light spread.

Not thinking about color rendering index (CRI), which changes how colors look.

Skipping a full check of the building or lighting needs.

Putting lights in the wrong spots, missing dark or important places.

Choosing bad fixtures from suppliers you cannot trust.

Not making sure lights work with lighting controls.

These mistakes can mean less energy savings and more money spent on repairs. Facility managers should plan well, pick the right products, and make sure lights are put in the right way. Staying away from these mistakes helps keep ROI high and payback fast for every LED upgrade. Good planning and smart choices make energy-saving lighting work for a long time.

Facility managers can use easy steps to figure out LED high bay lighting ROI. First, they collect information about their lights. Next, they guess how much energy and maintenance money they will save. Then, they find out how long it takes to get their money back. They use the ROI formula to see if the project is worth it. Counting all savings and any special deals makes the answer more correct.

For the best results, managers should follow these steps and use the formulas for their own buildings. They can also ask lighting experts or try online calculators to make sure their math is right.

FAQ

How does LED high bay lighting reduce energy costs?

LED high bay lighting uses less electricity than old lights. This technology turns more power into light, not heat. When places switch to LEDs, their utility bills go down.

What factors affect the payback period for LED upgrades?

Many things change how fast you get your money back. These include energy prices, how long lights are on, fixture wattage, and rebates. If energy costs are high or lights run longer, payback is faster.

Can facilities receive rebates for LED high bay lighting projects?

Yes, lots of utility companies give rebates for LED upgrades. Facility managers should look for local rebate programs. Rebates make the first cost lower and help ROI get better.

How often do LED high bay lights need maintenance?

LED high bay lights last much longer than old bulbs. Most fixtures work for 50,000 hours or even more. This means you do not have to replace them as often, so maintenance costs go down.

Is it necessary to include maintenance savings in ROI calculations?

Adding maintenance savings makes ROI more correct. LED lights need less work, so places save on labor and parts. Always count both energy and maintenance savings for the best results.