Choosing the Perfect LED Light Fixtures for Your Warehouse focusing on Efficiency, Brightness, and Cost Analysis

When you choose LED light fixtures for your warehouse, focus on efficiency, brightness, and cost. Good lighting for warehouses keeps workers safe and helps them work faster. LEDs use much less energy than other bulbs, saving you money every month. Many warehouses see energy costs drop by up to 83% with LED lighting and smart controls. LED bulbs last much longer, so you spend less on replacements and repairs. Companies often save tens of thousands of dollars, sometimes even $100,000. You can see payback in three to five years, making LED lighting a smart choice for your warehouse, Home, About Us, and Product spaces.

Key Takeaways

LED lights use up to 80% less energy. They help lower electricity bills a lot. This makes them a good choice for warehouses.

Pick LED fixtures with high brightness, called lumens. Choose the right color temperature, between 4000K and 5000K. This helps workers stay safe and work better.

LED lights last much longer than old bulbs. This means you spend less on fixing and replacing them over time.

Plan your lighting by measuring your space first. Match the fixtures to your ceiling height. Use smart controls like motion sensors to save even more energy.

Buying good LED fixtures saves money in 2 to 5 years. You save on energy and repairs. This makes your warehouse safer and more efficient.

LED Efficiency

Energy Savings

Switching to LED fixtures saves a lot of energy. Commercial LED lighting uses much less power than incandescent lamps. Some LED systems can save up to 90% energy in the best cases. Most warehouses save about 55-75% on energy costs with LEDs. This means your electricity bill goes down every month. Pick LED fixtures with high lumen output per watt for best results. Experts say you should get at least 140 lumens per watt in warehouses. This helps you get bright light and use less energy. Using energy-efficient lighting saves money and helps the environment.

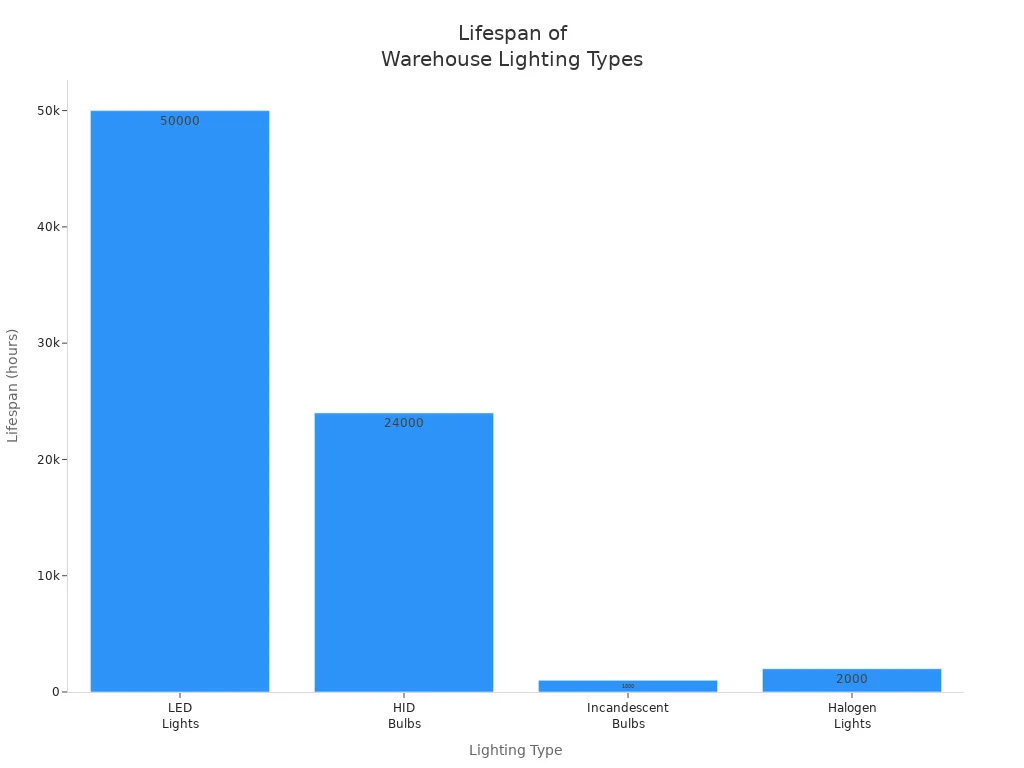

Fixture Lifespan

LED fixtures last much longer than old bulbs. LED lights can work for 25,000 to over 50,000 hours. This means you can use them for 9 to 20 years, depending on how long you keep them on each day. HID bulbs last 3 to 7 years, and incandescent bulbs last less than a year. The table below shows how long each type lasts:

Lighting Type | Lifespan Range (hours) | Estimated Years of Use (based on daily usage) |

|---|---|---|

LED Lights | 25,000 - 50,000+ | 9 - 20 years |

10,000 - 24,000 | 3 - 7 years | |

Incandescent Bulbs | ~1,000 | Less than 1 year |

Halogen Lights | ~2,000 | 1 - 2 years |

Maintenance

LED fixtures need less maintenance than other lights. LEDs are tough and do not break easily. High IP ratings like IP65 or IP67 keep out dust and water. This helps your lights last longer, even in hard warehouse conditions. Clean your lights and check the seals to keep them working well. Lighting controls like motion sensors and daylight sensors help save more energy. These controls can cut energy use by 30-40%. Automated systems and remote monitoring make it easy to control your lights. Modular LED solutions let you add or upgrade lights as your warehouse grows. This helps you save energy for many years.

Warehouse Brightness

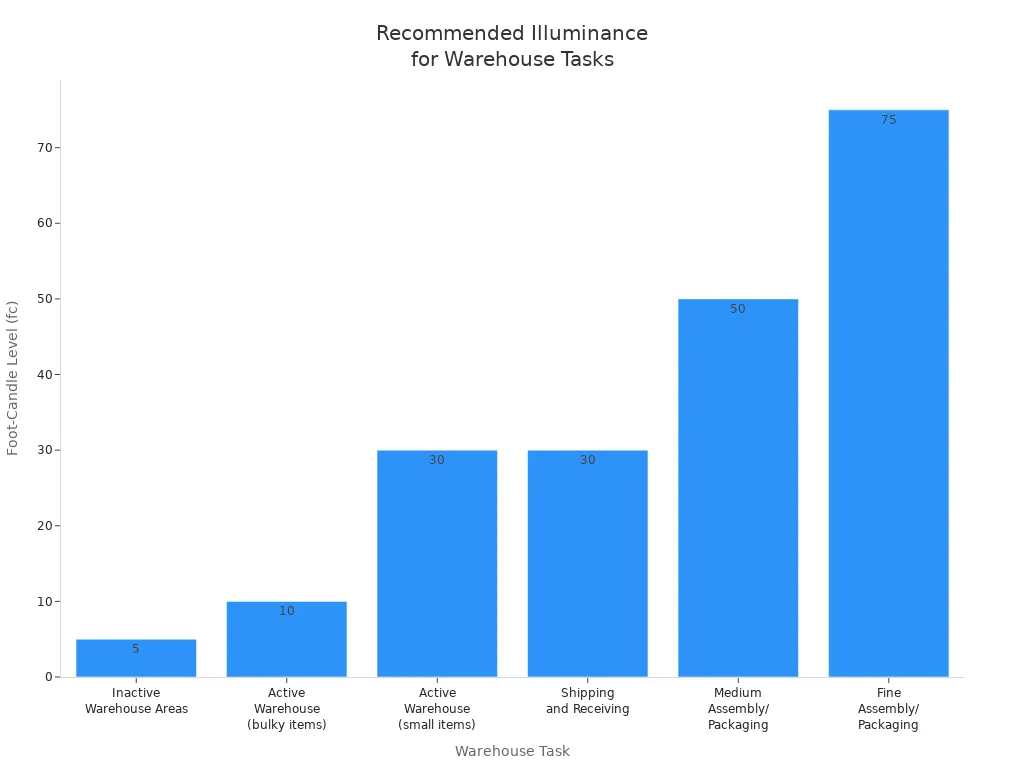

Lumen Output

You need enough brightness in every warehouse area. First, measure the space and ceiling height. Then, think about what jobs happen in each zone. Some jobs, like storing things, do not need much light. Other jobs, like packing, need more light. Use foot-candle levels to set your goal. General storage needs 10-30 foot-candles. Fine assembly can need up to 100 foot-candles. Multiply your area by the foot-candle number to get total lumens. This helps you pick led warehouse lights with enough output for safety and work.

Warehouse Task | Recommended Foot-Candle Level |

|---|---|

Inactive Warehouse Areas | 5 fc |

Active Warehouse (bulky items) | 10 fc |

Active Warehouse (small items) | 30 fc |

Shipping and Receiving | 30 fc |

Medium Assembly/Packaging | 50-70 fc |

Fine Assembly/Packaging | 75-100 fc |

Color Temperature

Color temperature in led lighting changes how well people see. Most warehouses use lights between 4000K and 5000K. This light looks like daylight and helps workers stay alert. In places where workers need to focus, use cool white lights up to 6000K. For offices or break rooms, use warmer lights from 2700K to 3500K. Picking the right color temperature makes work safer and helps people do their jobs better.

Tip: Use cooler color temperatures in work zones to help workers pay attention and make fewer mistakes.

Fixture Placement

Putting fixtures in the right spots gives even light everywhere. High bay fixtures are good for tall ceilings. UFO-style led fixtures work for both high and medium ceilings. Place fixtures so light spreads out and there are no dark spots. Good placement helps people see better and keeps them safe. Use reflectors and lenses to send light where it is needed most. When planning warehouse lighting, always check that fixture placement helps people work safely and well.

Cost Analysis for LED Warehouse Lights

Upfront Costs

When you want new lighting, you need to think about the first costs. These costs include buying fixtures, paying for installation, and getting extra materials. The table below shows what you might pay for LED warehouse lights:

Cost Component | Estimated Cost per Square Foot (USD) |

|---|---|

Indoor Lighting & Electricity | $3.20 - $4.00 |

Labor (Standard Installation) | $3.90 - $6.50 |

Labor (Complex Installation) | $6.50 - $10.40 |

Materials (Standard Quality) | $5.20 - $7.80 |

Materials (High Quality) | $7.80 - $13.00 |

Each LED bulb can cost about $3.50. Electricians charge between $50 and $300 for each hour they work. It takes one or two hours to install each fixture. These costs can be high if your warehouse is big or has tall ceilings. Labor is usually 35-45% of the total cost.

Long-Term Savings

LED warehouse lights help you save money for many years. They use up to 75% less energy than older lights. You also spend less on fixing them because LED fixtures last longer. Many warehouses see maintenance costs go down by 60-80%. For example, if you put in 1,000 LED bulbs at $50 each, you spend $50,000 at first. But you could save about $10,000 every year on electricity. After a few years, these savings cover what you paid at the start.

Tip: If your lights are on for more hours each day, you save money faster because you use less energy and need fewer repairs.

ROI

You can figure out your return on investment (ROI) by seeing how fast your savings pay back your first costs. Here is an easy way to find payback:

Check how much less energy your new lights use.

Multiply by how many fixtures you have and how many hours you use them each year.

Multiply by your electricity price to get yearly savings.

Add what you save on repairs.

Divide your first cost by your yearly savings.

Most warehouses get their money back in two or three years. For example, one warehouse saved $34,000 on energy and $4,400 on repairs after switching to LED fixtures. Their payback time was just over two years. Their ROI was up to 41% with rebates. After you get your money back, all the savings help your business.

Choosing LED Light Fixtures

Assessment Checklist

When you choose led light fixtures for your warehouse, you need a clear plan. Use this step-by-step checklist to make sure you cover all important points:

Measure your space. Look at the layout, ceiling height, and what activities happen in each area.

Decide how much light you need. Use recommended foot-candle levels for each zone. For example, general areas need 10-20 foot-candles, while workstations need 30-50.

Pick led light fixtures with high energy efficiency. Look for at least 120 lumens per watt for commercial-grade led.

Check the color temperature. Most warehouses work best with 4000K to 5000K for clear, cool white light.

Make sure the Color Rendering Index (CRI) is at least 80. This helps workers see colors clearly and avoid mistakes.

Choose fixtures with high IP ratings, like IP65 or higher. These ratings protect against dust and moisture.

Plan for zoning. Use brighter lighting for packing stations and softer light for storage.

Add smart controls. Motion sensors and dimmers help save energy and adjust lighting as needed.

Include emergency lighting systems for safety during power outages.

Place fixtures to remove shadows and dark spots. This step helps with maximizing visibility and safety.

Think about natural light. Use windows or skylights to lower energy use and improve worker comfort.

Set up a maintenance schedule. Clean fixtures and check for problems often.

Tip: Always follow OSHA rules for lighting. Keep fixtures at least 7 feet above work areas and use protective covers to prevent accidents.

Comparing Options

You have many types of led light fixtures to choose from. Each type works best in certain parts of the warehouse. Here is a table to help you compare options based on ceiling height and brightness needs:

Ceiling Height (feet) | Recommended Lumen Output | Fixture Type | Typical Spacing (feet) |

|---|---|---|---|

20-30 | 22,000 - 35,000 | UFO High Bay | 15 - 25 |

31-40 | 35,000 - 47,000 | Linear High Bay | 19 - 29 |

40+ | 47,000+ | High Bay/Custom | 30 - 40 |

UFO high bays give wide, bright light for large open spaces.

Linear high bays work well in long aisles and narrow spaces.

Wall packs add extra lighting around the outside for security.

LED strip lights fit under shelves or in tight spots.

When you compare led light fixtures, look for high lumens per watt (130 or more) to get the most energy savings. Match the beam angle to your ceiling height. For tall ceilings, use a narrow beam to focus light. For lower ceilings, use a wider beam for even coverage. Always check if the fixtures are easy to install and can adapt if you change your warehouse layout later.

Note: Modular and scalable led solutions let you add or move fixtures as your warehouse grows. This flexibility saves you money and time in the future.

Final Selection

Now you are ready to make your final choice. Follow these steps to pick the best led light fixtures for your warehouse:

Set your project goals. Decide if you want to save energy, improve lighting quality, or prepare for future changes.

Gather details about your current lighting. List fixture types, wattage, and how long they run each day.

Focus on quality. Avoid cheap fixtures that may fail early or cause problems. Choose vapor-tight fixtures if your warehouse has moisture.

Make sure fixtures have the right IP rating and can handle high temperatures if needed.

Pick the right mounting option. Use high bay fixtures for ceilings over 25 feet and low bay for lower ceilings.

Plan your lighting layout. Place fixtures to avoid glare and shadows, which helps with maximizing visibility and safety.

Check for OSHA compliance. Fixtures must have protective covers, be mounted at least 7 feet high, and have no exposed live parts.

Consult with a lighting specialist. They can help you design the best system for your needs.

Use smart controls and modular systems to future-proof your investment.

Test your new lighting after installation. Make sure it meets your goals for brightness, energy use, and safety.

Remember: Good led lighting improves worker safety, lowers energy bills, and keeps your warehouse ready for future changes. Always choose quality fixtures and plan for both current and future needs.

You can achieve the best results in your warehouse by following a clear, step-by-step process for choosing LED fixtures:

Assess your space and tasks.

Select fixtures that match your ceiling height and work zones.

Use smart controls to save energy and reduce costs.

LED lighting reduces energy use by up to 80%, lowers maintenance, and improves safety. Case studies show quick payback and long-term savings. Make smart choices to boost productivity and cut expenses.

FAQ

What is the best color temperature for warehouse LED lights?

Most warehouses work best with 4000K to 5000K LED lights. This range gives you bright, clear light that looks like daylight. Workers see better and stay alert. Use cooler lights for work areas and warmer lights for offices.

How do I know how many LED fixtures my warehouse needs?

First, measure your warehouse size and ceiling height. Check the tasks in each area. Use the recommended foot-candle levels for each zone. Multiply the area by the foot-candle number to find the total lumens needed. Then, choose fixtures that match this output.

Do LED lights work in cold or damp warehouse environments?

Yes, LED lights work well in cold and damp places. Choose fixtures with high IP ratings like IP65 or IP67. These ratings protect against dust and water. LEDs turn on instantly, even in freezing temperatures.

Can I save money by switching to LED warehouse lighting?

You can save up to 80% on energy costs by switching to LED lights. LEDs last longer and need less maintenance. Many warehouses see payback in two to three years. After that, you keep saving money every month.

Are LED warehouse lights safe for workers?

LED lights improve safety in warehouses. They give you bright, even light with fewer shadows. Workers see better and avoid accidents. LEDs also stay cool, so they lower fire risks. Always follow OSHA rules for lighting safety.